Wafer Check Valve Manufacturer for Compact Lines

Key features:

Robust streamlined design – Our industrial wafer check valve is engineered for durability while maintaining simplicity in structure.

Leak-proof performance – Precision manufacturing ensures 100% leak proof sealing under demanding operating conditions.

Compact dimensions – Optimized valve dimensions allow for short face-to-face length, saving installation space.

Lightweight construction – The design reduces overall weight, simplifying handling and installation.

Superior flow characteristics – Hubluxe ensures efficient flow dynamics and consistent performance for all the valves.

Cost-effective solution – Without compromising on quality, Hubluxe is a trusted wafer check valve manufacturer choice for industries worldwide.

Contact Hubluxe Engineering today for a competitive quote.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Recognized as a renowned industrial check valve manufacturer, we combine technical mastery with innovative design for superior reliability.

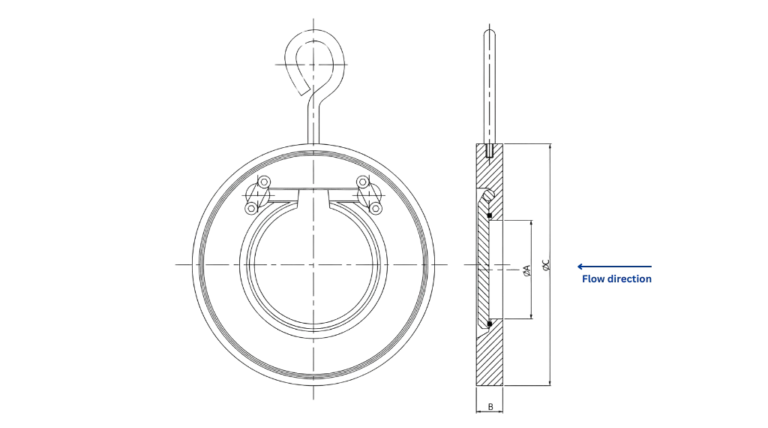

As a quality industrial manufacturer, HUBLUXE Engineering provides high-performance Wafer Check Valves designed for critical backflow prevention in compact piping networks. Our product range includes both the Single Plate Wafer Check Valve and the Spring-Loaded Non-Return Valve, both engineered to meet API 6D and ASME B16.34 manufacturing standards. By utilizing a specialized ‘sandwich’ design that fits securely between flanges, these Compact Non-Return Valves reduce overall weight by up to 90% compared to conventional swing designs, significantly lowering installation costs. For advanced safety, our DCV3 Spring Loaded Check Valve is built to API 594 specifications, utilizing a precision-tensioned mechanism to eliminate water hammer and ensure leak-proof sealing across HVAC, oil & gas, and steam process lines globally. |

Single plate check valve & Spring Loaded Check Valve:

Technical Data:

Product: ‘HUBLUXE’ Single Plate Wafer Check Valve

- Size Range: DN25 – DN300 (1” – 12”)

Body Materials: Cast Iron (CI) / WCB / SS304 / SS316 / SS316L

Disc: MS / WCB / SS304 / SS316 / SS316L

Seat: Metal to metal / Nitrile / EPDM / Silicon / Viton / PTFE

Hinge Pin: AISI 304 / 316 / 304L / 316L

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Manufacturing Standards & dimensions:

Design & manufacturing standard: API 6D / ASME B16.34

Face to face standard: API 6D / ASME B16.10

- End connection: Flange end as per ANSI B16.5 – 150#

Testing: API 598 / BS EN 12266-1

Pressure rating: 150# / 300# / ND10 / ND16 / ND40

- Hydro test pressure details: Body: 24 kg/cm2, Seat: 16 kg/cm2

| Sr. No. | Part Name | Material |

|---|---|---|

| 1 | Body | Cast Iron (CI) / WCB / SS304 / SS316 / SS316L |

| 2 | Disc | MS / WCB / SS304 / SS316 / SS316L |

| 3 | Seat | Metal to metal / Nitrile / EPDM / Silicon / Viton / PTFE |

| 4 | Hinge Pin | AISI 304 / 316 / 304L / 316L |

| 5 | Lifting Hook | MS / SS304 / SS316 |

Technical Data:

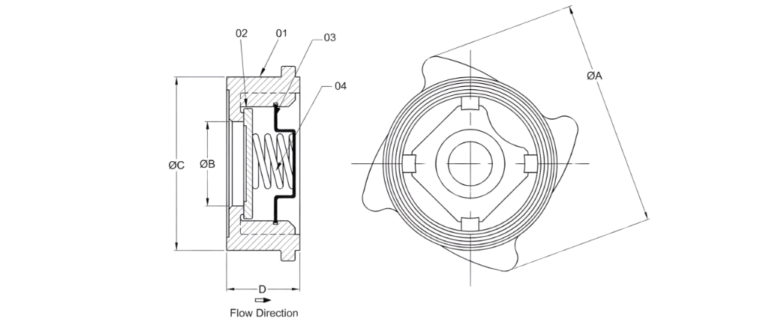

Product: ‘HUBLUXE’ Spring loaded Disc check valve (non-return) / Non slam check valve

Size: DN15 to DN200 (1 ½” to 8”)

Body: Stainless steel SS304 / SS316 / SS 316L

- Disc: Stainless steel SS304 / SS316 / SS 316L

Spring: AISI 304 / AISI 316

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Manufacturing Standards & Non-slam check valve dimensions:

Design & manufacturing standard: Manufacturer’s standard

Testing standard: API 598

Face to face dimensions: Manufacturer’s standard

Pressure rating: PN10 / PN16 / PN25 / PN40

| Sr. No. | Part Name | Material |

|---|---|---|

| 1 | Body | CF8 / CF8M / CF3M / 4A / 5A |

| 2 | Disc | CF8 / CF8M / CF3M / 4A / 5A |

| 3 | Seat | Metal to metal / Nitrile / EPDM / Silicon / Viton / PTFE |

| 4 | Spring | AISI 304 / 316 / 304L / 316L / Inconel X750 / X718 |

| 5 | Spring retainer | SS304 / SS316 |

Note: It is not recommended for installation in pulp lines & compressor delivery lines.

At Hubluxe Engineering, we redefine pipeline efficiency with our high-performance Check Valves range (Non Slam Check Valve / Disc Check Valve / Spring Loaded Check Valve). Engineered to address the bulk and weight limitations of traditional flanged valves, our Valves offer a streamlined, space-saving solution without compromising on flow capacity or durability.

Check valve applications:

- Pharmaceuticals

- Chemical

- Textile

- HVAC

- Steam & condensate line

- Oil & gas

- Heating & ventilation

- Water treatment

- Boilers

- Beverages

- Hot & cold-water system

FAQs (Frequently asked questions)

Find detailed answers to common questions about Wafer check valve & Non slam check valve in our Knowledge centre.

Non slam check valves are lift type NRV (non-return valve) used in pipelines to prevent backflow. The non slam check valves have short length, compact design to fit between two flanges. This offers advantages in terms of installation, handling, and easy maintenance.