HUBLUXE make Gate valves

Hubluxe Engineering manufactures Gate valve in accordance with International Industrial standards. We follow stringent quality checks for selecting finest quality of raw materials for gate valve & we are known for quality gate valve manufacturer in India.

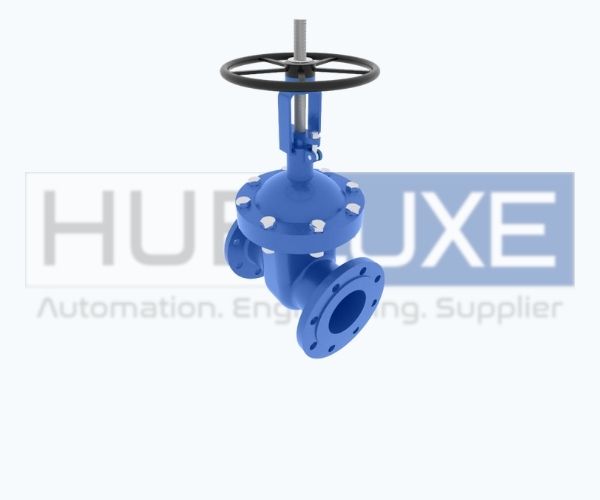

Gate Valve (Rising stem)

Gate Valve

Forged Gate valve

Gun-metal Gate valve

Non rising Gate valve

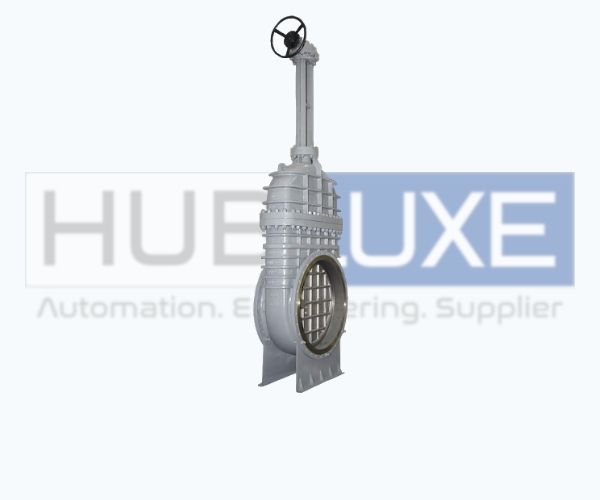

Knife Gate valve

Gate valves are also known as Isolation valves and they are designed for fully open or fully close service. Gate valves should not be used as control or regulating valves.

Hubluxe offers Gate valves that are highly efficient, long lifecycle, easy to install and budget-friendly. We manufacture following types of Gate valves for wide area of application:

Size: 15 mm to 600 mm (½” to 24”)

Class: ASME 150# to ASME 2500#

End connection: Flanged End, Butt Weld End

Design Type: OS & Y Construction, Flexible Wedge Design, Full Port Design, Pressure Seal Bonnet or Welded Bonnet

Operation: Hand wheel, Gear operated, Actuator (Pneumatic, Electrical motorised, Hydraulic)

MATERIAL OF CONSTRUCTION:

Body: ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Trim: 13% Cr Steel, SS304, SS304L, SS316, SS316L, 321, 347, F51, Monel, Stellite etc.

Standards followed:

Inspection & Testing: API 598, ISO 5208

Design: API 600, BS 1414

Types: Uni-directional, Bi-directional

Size: 50 mm to 2000 mm (larger size on request)

Body: Cast Iron, SGI, WCB, SS304, SS316, Haste Alloy etc.

Gate: WCB, SS304, SS316, 317 Stainless Steel, Hastelloy® C, Monel®, Titanium

Seat ring: Metal to metal, V-Port, also available in EPDM/VITON/PTFE/NITRILE

Operation: Manual, Gear, Pneumatic, Electrical actuator & Chain operating

Actuator options: Direct Mounted Handwheel, Bevel Gear Operator, Double Acting Pneumatic Actuator, Hydraulic Actuator, Electrical Actuator

Working Pressure: 3 kg/cm2 to 10 kg/cm2 (45 psi to 150 psi)

Temperature: -40 deg. C to 1200 deg. C

Flange connection: ANSI B16.5 class 150#, EN1092 PN6/16/25, BS "D" & "E" ANSI 125

Port type: Two-lug, full lugged, Semi lugged, Flange design, Wafer flangeless

Design standard: MSS SP-81 which applies to metal seated knife gate valves while Resilient seated knife gate valves are not designed under MSS SP-81

Testing standard: As per MSS SP-81

Application: Pulp & paper, Mining, Primary Milling, Ash handling, Chemical plants, Food & beverages, Wastewater treatment, Process pumps

Size: 15 mm to 600 mm (½” to 24”)

Class: ASME 150# to ASME 2500#

End connection: Flanged End, Butt Weld End

Design Type: OS & Y Construction, Flexible Wedge Design, Full Port Design, Pressure Seal Bonnet or Welded Bonnet

Operation: Hand wheel, Gear operated, Actuator (Pneumatic, Electrical motorised, Hydraulic)

MATERIAL OF CONSTRUCTION:

Body: ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Trim: 13% Cr Steel, SS304, SS304L, SS316, SS316L, 321, 347, F51, Monel, Stellite etc.

Standards followed:

Inspection & Testing: API 598, ISO 5208

Design: API 600, BS 1414

Size: 15 mm to 600 mm (½” to 24”)

Class: ASME 150# to ASME 600#

End connection: Flanged End, Butt Weld End

Design Type: OS & Y Construction, Flexible Wedge Design, Full Port Design, Pressure Seal Bonnet or Welded Bonnet

Operation: Hand wheel, Gear operated, Actuator (Pneumatic, Electrical motorised, Hydraulic)

MATERIAL OF CONSTRUCTION:

Body: ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Trim: 13% Cr Steel, SS304, SS304L, SS316, SS316L, 321, 347, F51, Monel, Stellite etc.

Standards followed:

Inspection & Testing: API 598

Design: API 6D

Application areas

- Water supply

- Pulp & slurry

- Automotive

- Waster water

- Pharmaceuticals

- Air, Fuel, Gas

- LNG & Hydrocarbon industries

- Steel & Power

- Ports & shipping

Interested to know more about Gate valves?

We shall be glad to hear on your queries about the Gate valves. Our team can aid in guiding and selecting the valves required for your most critical applications.

Business Phone

+91 22 27830855

+91 22 49714236