V-Notch Ball Valves (Segmented V-Port Control)

Key features:

Single piece body design ensures almost no leakage

Shearing effect between ball and seal enables tight shut-off on fibrous slurries

Unrestricted, straight-through flow provides high capacity

V-notch design allows near equal-percentage flow characteristics

Replaceable seals and backup rings ensure extended valve life

Super-finished, hard chrome-plated ball enhances durability

- High Cv-to-Size Ratio: Optimized internal geometry enables compact sizing while maintaining high flow capacity

- Flexible Seating Options: Soft and metal seats available for varying process requirements

Precision Control. Zero Clogging. Choose Hubluxe Engineering, the trusted V Notch Ball Valve manufacturer, for precise throttling and isolation in tough environments.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Hubluxe Engineering, is specialized V Notch Ball Valve manufacturer, offering a high-performance, non-clogging valve solution engineered for precision flow control in demanding industrial environments. Ideal for applications involving pulp, slurries, or fluids with suspended solids, our valves ensure efficient, uninterrupted flow. Also known by V Port Ball Valve or Segmented Ball Valve names.

Available V-Port Profiles:

- 30° V-Notch: For fine control and low flow rates.

- 60° V-Notch: For general control applications.

- 90° V-Notch: For high flow capacity and slurry services.

Our V Notch Ball Valve is designed for real-world challenges — where performance matters most. Contact us today to discuss sizing, materials, and actuator options tailored to your project.

V-Notch Ball Valve (Segmented V-Port) technical specifications:

Product: ‘HUBLUXE’ V-Notch Ball Valve

Size: 15 mm to 300 mm (1/2” to 12”)

MOC Body: ASTM A216 Gr. WCB / ASTM A351 CF8 / CF8M / Alloy steel

Ball: CF8M, Chrome-Plated / Alloy Steel

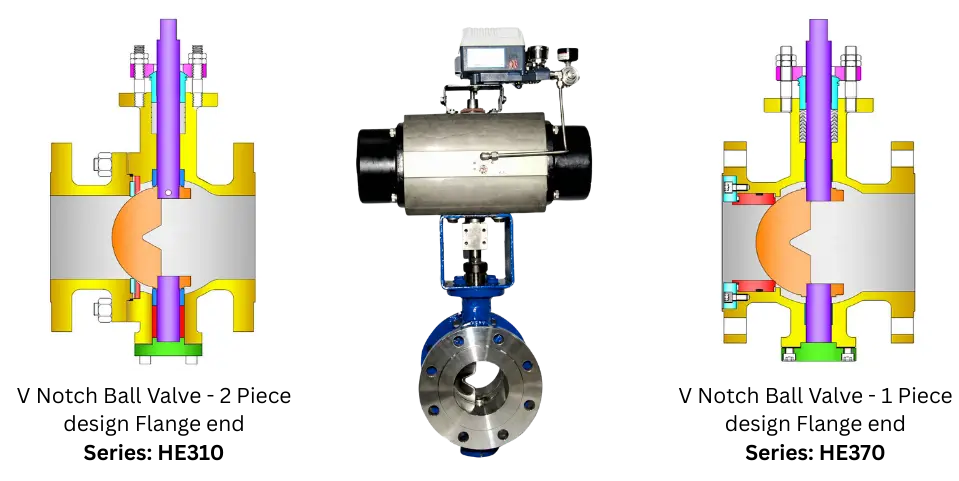

Design options: One piece design, Two-piece design

Model:

Series HE310 – Single piece design

Series HE370 – Two-piece design

Seat options: Soft seat & Metal to metal seat

Flow characteristics: Modified equal percentage, Linear, ON-OFF

Flow direction: Forward (Into Convex face of V-Ball)

Ball rotation: 90 degrees maximum

Rating: ANSI 150#

Design Std: BS 5351

End connection: Flange End

Face to face dimension: ANSI B16.10

Operation: Manual override, Diaphragm operated, Pneumatic cylinder, Electrical actuator

Air Connection: ¼” to ½”

Accessories:

- Valve positioner: Pneumatic, Electro pneumatic, Smart positioner

- Instruments: Airset, Solenoid valve, Air Lock, Volume Booster, Position Transmitter, Limit proximity switches etc.

- Features: Top or side mounted handwheel, Limit stops

Standard construction details of V-notch ball valve

| S.No. | Parameter | Specification |

|---|---|---|

| 1 | Design | BS. 5351 |

| 2 | Series | 310 - 2 Piece Design / 370 - 1 Piece Design |

| 3 | Size | 15 to 300 mm (1/2" to 12") |

| 4 | Rating | ANSI 150 |

| 5 | End Connection | Flanged End |

| 6 | F/F Dimensions | ANSI B-16.10 |

| 7 | Flow Characteristics | Modified Equal Percentage / Linear / On-Off. |

| 8 | Flow Direction | Forward (into convex face of V-ball) |

| 9 | Max. Ball Rotation | 90° |

| 10 | Body Material | Carbon Steel / Stainless Steel / And Alloy Steel etc. |

| 11 | Ball Material | CF8M Chrome plated/Alloy steels. |

| 12 | Seat | Soft / Metal Seat |

| 13 | Ball Ring | CF8M / Alloy steels. |

| 14 | Gasket | PTFE / Graphite Laminate. |

| 15 | Gland Packing | PTFE V Rings / Grafoil. |

| 16 | Actuator Form | Diaphragm / Rotary / Electric. |

| 17 | Air Connection | 1/4" or 1/2" NPT |

| 18 | Accessories | Valve Positioner-Pneumatic / Electro Pneumatic / Smart Positioner. Instruments-Airset / Solenoid Valve / Air Lock / Volume Booster / Position Transmitter / Limit Proximity Switches etc. Features- Top or Side Mounted handwheel / Limit Stops |

V notch Ball valve applications:

Pulp and paper– bleaching, digesting & stock preparation lines (shearing through wood pulp)

Chemical and petrochemical processes – Viscous fluid & polymer handling

Wastewater treatment – Sludge control & lime slurry

Slurry and abrasive media handling

Mining and power – Ash handling systems

FAQs (Frequently asked questions)

Find detailed answers to common questions about V-Notch Ball Valve (Segmented V-Port) in our Knowledge centre.

A V Notch Ball Valve (also called a V Port Ball Valve or Segmented Ball Valve) is a type of quarter-turn control valve where the ball features a “V” shaped cut instead of a standard round hole.

This unique V-profile creates a precise opening that allows for accurate throttling and flow regulation, similar to a globe valve but with higher flow capacity. The sharp edge of the V-notch also provides a shearing Effect, enabling the valve to cut through fibers and solids without clogging, making it ideal for paper pulp, slurries, and viscous fluids.

While both are quarter-turn valves, a V-Notch ball valve which has V-shaped opening offers precise throttling (flow control). Standard ball valves are typically on/off valves and can trap debris, waste etc, whereas V-Notch designs provide a self-cleaning effect.

Wafer type V notch ball valves are lighter, more compact, and cost-effective, fits between two pipe flanges. Flanged versions are more robust and easier to install/remove without disturbing the pipe alignment.