Unidirectional Knife Gate Valves (MSS-SP-81) for Slurry & Pulp

“High-Performance Unidirectional Knife Gate Valves for Paper & pulp, Slurry & Wastewater”

Hubluxe Engineering manufactures Unidirectional knife gate valves which is designed to handle the fluids containing slurries, pulp & paper waste, wastewater.

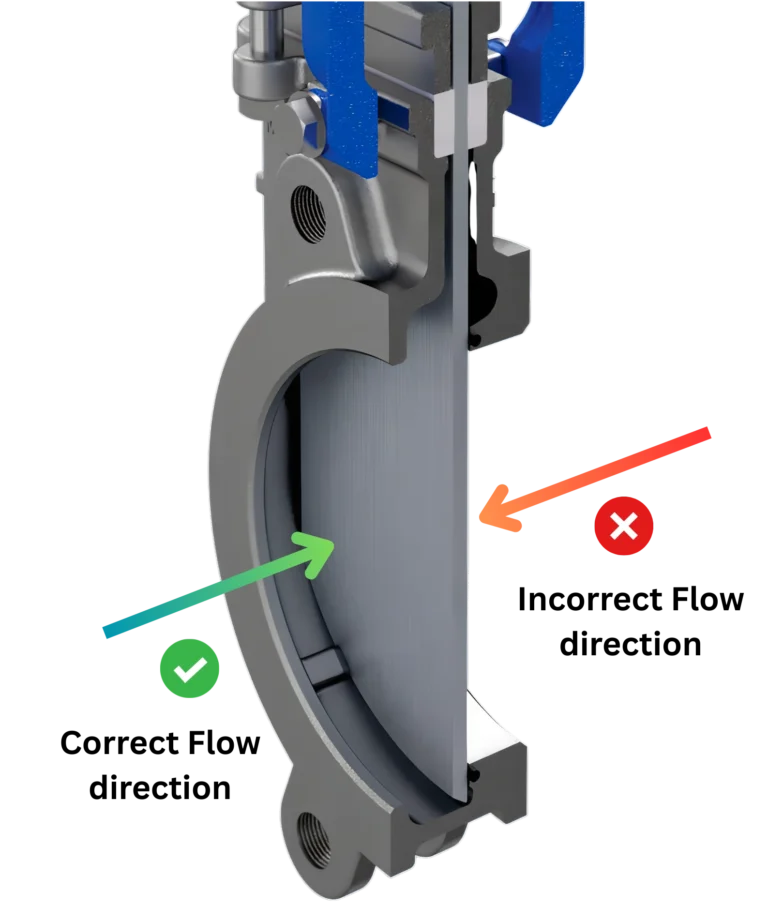

In Unidirectional Knife Gate Valve the valve is designed to withstand the pressure from one specific direction only.

The pressure of the fluids in the pipeline pushes the gate (the knife gate valve) against the seat to create a tight sealing which is why they are technically designed so and called as unidirectional knife gate valves.

Hubluxe Engineering manufactures both Wafer and Lug Type valves to MSS-SP-81 standards, specifically engineered to cut through heavy slurries, paper pulp, and wastewater without clogging.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

“High-Performance Unidirectional Knife Gate Valves for Paper & pulp, Slurry & Wastewater”

Hubluxe Engineering manufactures Unidirectional knife gate valves which is designed to handle the fluids containing slurries, pulp & paper waste, wastewater.

In unidirectional mechanism the valve is designed to withstand the pressure from one specific direction only.

The pressure of the fluids in the pipeline pushes the gate (the knife gate valve) against the seat to create a tight sealing which is why they are technically designed so and called as unidirectional knife gate valves.

Key Engineering Advantage:

Due to Uni flow direction it ensures excellent sealing & prevents backflow from potential system damage. Also, the cost of valve is relatively lower when compared to bidirectional knife gate valves.

Why Choose Unidirectional? If your system does not require backflow prevention, our Unidirectional Series (HE-MS/HE-MD) provides superior sealing performance at a lower cost compared to bi-directional alternatives, with higher wear resistance in abrasive media.

Knife gate valve specifications – Standard technical specifications for Unidirectional Knife Gate valves are as follows:

- Valve design Type: Unidirectional Knife Gate valve (KGV)

- Size: DN 50 – DN 1600 (2” to 64”) – Higher sizes on request

- Pressure rating: PN6, PN10, PN16, 150#

- Material of construction (MOC): Cast Iron, Ductile Iron, GGG40, Cast Steel (WCB), SS304 (CF8), SS316 (CF8M), SS316L (CF3M) – other materials on request

- Seat options: Metal to Metal, Soft seat (EPDM, Nitrile, Viton, Silicone, PTFE)

- Lug options: Full Lug, Semi Lug, Double Flange, Square type

- Gland Packing options: Pure PTFE, PTFE impregnated synthetic fiber, PTFE w/Buna-N quad seal, PTFE w/Viton quad seal, PTFE w/EPDM quad seal, PTFE w/Copper Wiper, Graphite

- Operation: Manual, Pneumatic, Chain wheel operated, Electrical actuator, Bare shaft, Gearbox operated, Manual override

- Applications: Paper & pulp, Waste water treatment plants, Power plants, Food & Beverage, Mining & Steel plant, Oil & Gas, Chemical plant, Pharma & Sugar Industries, Bulk materials & slurry applications

- Design standard: MSS-SP-81

- Testing standard: MSS-SP-81

- Face to face standard: MSS-SP-81

- Standard flange connection: PN10 & ANSI B16.5 (150#) with Table ‘E’ & ‘D’, PN6, PN16, PN25, ANSI125

Gland Packing Material & Temperature Selection Guide:

Leak-Free Performance for Every Application The sealing efficiency of a Knife Gate Valve depends entirely on the correct Gland Packing selection. At Hubluxe, we offer a versatile range of packing materials engineered to handle extreme temperatures, aggressive chemicals, and abrasive slurries.

Standard Service (Pure PTFE): Ideal for general chemical and acid applications up to 260°C, offering low friction and excellent corrosion resistance.

Zero-Fugitive Emission (Quad Seal Technology): Our advanced PTFE with Quad Seal (Viton®/EPDM) design provides a dynamic live-loaded seal. This multi-stage sealing prevents fugitive emissions, making it perfect for hazardous gases and strict environmental compliance.

High Temperature (Graphite): For power plants and ash handling, our braided Graphite Packing withstands temperatures up to 650°C (1202°F) without losing structural integrity.

Abrasive Slurry (Copper Wiper): Specifically designed for mining and sugar industries, the Copper Wiper acts as a scraper, removing dried slurry and solids from the gate surface during operation to protect the primary seal from damage.

Metal to metal

For applications with:

• High Temperature

• High density media

• When Full tightness not required

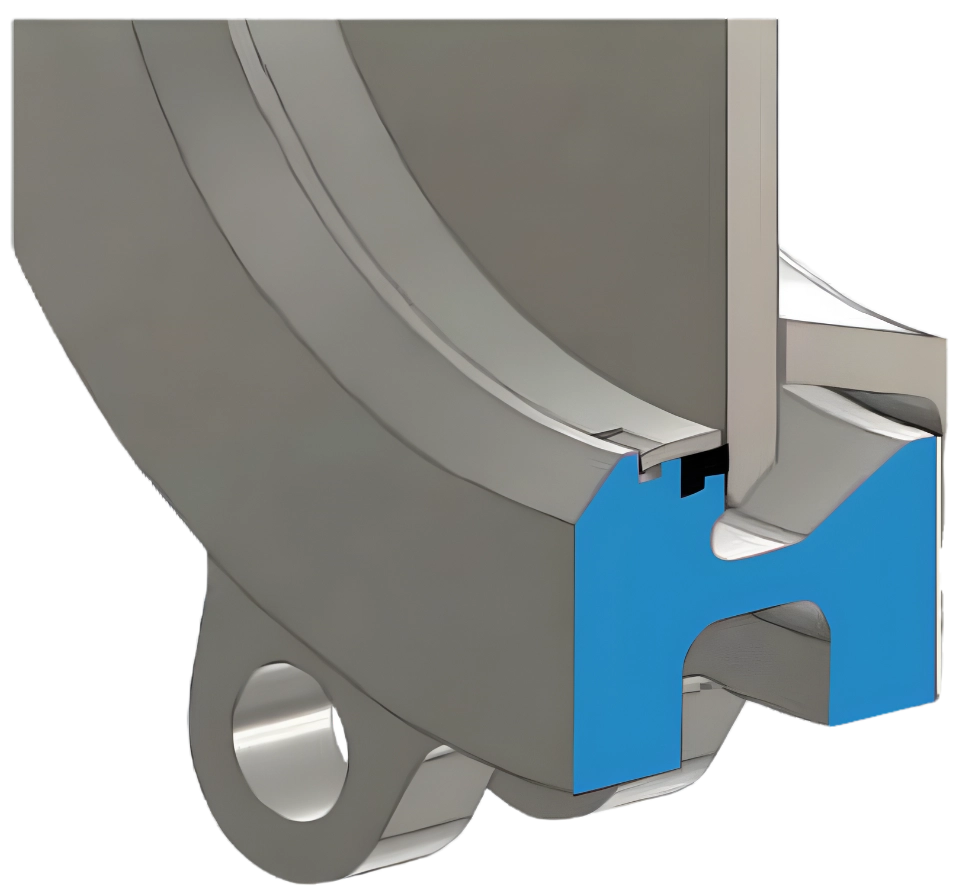

RESILIENT, Type “B”

For applications with:

• Temperature limitations according to the selected seat material. Review the above chart or contact us for more information.

• Replaceable and reinforced seat ring available in different material grades such as AISI 316 (1.4401), CA15, Ni Hard, etc.

RESILIENT, Type “A”

• Standard resilient seat

• Temperature limitations according to seat material selected. Review the above chart or contact us for more information.

• Replaceable seat retainer ring

DEFELCTION CONE “C”

• Deflects the media away from any valve internal exposed parts (gate, seat.. etc)

• Material: AISI 316 (1.4401), CA15, Ni Hard, PU etc.

• Face to face dimension increases:

DN 50 to DN 250 x = 9mm

DN 300 to DN 600 x = 12mm

Choose the Right Seat for Your Application:

Metal to Metal (High Temp): Best for Unidirectional Knife Gate Valves in high-temperature service or viscous media (tar, pulp) where absolute tightness is not critical but durability is key.

Resilient Seat (Type A & B): Provides Zero Leakage shut-off. ‘Type B’ features a reinforced ring (SS 316 or Ni-Hard) to protect the rubber seal from cutting, extending the life of your valve in abrasive conditions.

Deflection Cone “C” (Anti-Abrasion): A must-have for mining and heavy slurry. This cone deflects abrasive media (sand, rocks) away from the seat and gate, preventing internal wear. Available in Ni-Hard or Polyurethane (PU).

Customization: Actuation & Control Options

Unidirectional knife gate valve models:

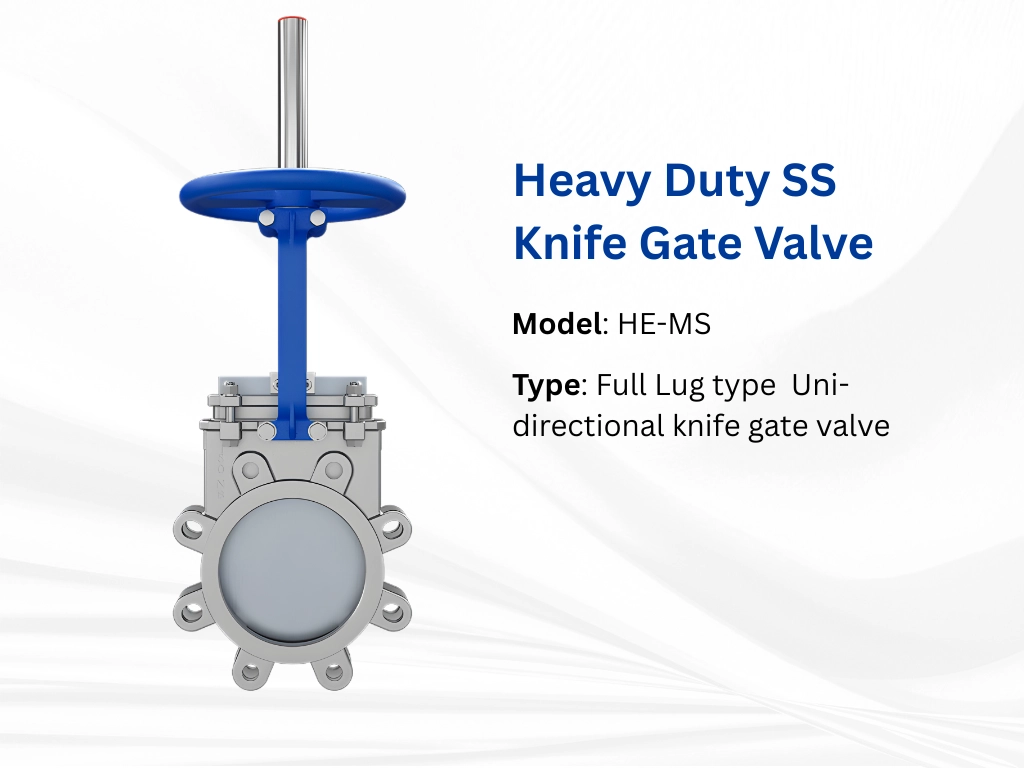

Model: HE-MS

Technical Data:

- Material of construction [MOC]:

Stainless steel (CF8, CF8M, CF3M etc.) – other materials on request

- Size :

DN50-DN1000 (2” to 40”) – Higher size on request

- Working Pressure :

DN 50 – DN 250 [10 bar], DN 300 – DN 400 [6 bar], DN 450 [5 bar], DN 500 – DN 600 [4 bar], DN 700 – DN 1200 [2 bar]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-MS model is a Unidirectional & bidirectional lug type valve which is designed according to MSS-SP-81 for industrial applications.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Power plants, waste water treatments, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

Model: HE-MS2

Technical Data:

- Material of construction [MOC]:

Stainless steel (CF8, CF8M, CF3M etc.) – other materials on request

- Size :

DN 50-DN 500 (2” to 20”)

- Working Pressure :

DN 50 – DN 250 [10 Kg/cm2], DN 300 & above [5 kg/cm2]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-MS2 model is a UNIDIRECTIONAL & BIDIRECTIONAL Semi lug type valve which is designed according to MSS-SP-81 for industrial applications.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Waste water treatments, Bulk handling, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

Model: HE-MD

Technical Data:

- Material of construction [MOC]:

Ductile Iron, Cast Iron, GGG40, GGG50

- Size :

DN 50-DN 1100 (2” to 44”)

- Working Pressure :

DN 50 – DN 250 [10 bar], DN 300 – DN 400 [6 bar], DN 450 [5 bar], DN 500 – DN 600 [4 bar], DN 700 – DN 1200 [2 bar]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-MD model Knife Edge gate valve is a UNIDIRECTIONAL & BIDIRECTIONAL Wafer Semi lug type valve which is designed according to MSS-SP-81 for industrial applications.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Waste water treatments, Bulk handling, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

Model: HE-MG

Technical Data:

- Material of construction [MOC]:

CF8, CF8M, Ductile Iron, Cast Iron, GGG40, GGG50

- Size :

DN 50-DN 1200 (2” to 48”)

- Working Pressure :

DN 50 – DN 250 [10 bar], DN 300 – DN 400 [6 bar], DN 450 [5 bar], DN 500 – DN 600 [4 bar], DN 700 – DN 1200 [2 bar]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-MG model is Gearbox operated Knife Edge gate valve which can be offered in UNIDIRECTIONAL & BIDIRECTIONAL design. This model comes in semi lug type, designed according to MSS-SP-81 for industrial applications.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Waste water treatments, Bulk handling, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

Model: HE-MP2

Technical Data:

- Material of construction [MOC]:

WCB, CF8, CF8M – other materials on request

- Size :

DN 50-DN 1000 (2” to 40”)

- Working Pressure :

DN 50 – DN 250 [10 bar], DN 300 – DN 400 [6 bar], DN 450 [5 bar], DN 500 – DN 600 [4 bar], DN 700 – DN 1000 [2 bar]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-MP2 model Pneumatic Knife Edge gate valve is a UNIDIRECTIONAL & BIDIRECTIONAL Lug type valve which is designed according to MSS-SP-81 for industrial applications.

The Pneumatic Knife Gate valves can also be provided along with accessories as per site requirement like: Limit switch, Air filter regulator, Solenoid valve, Connection tubing [PU, Stainless steel], Manual override.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Waste water treatments, Bulk handling, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

Model: HE-MDP

Technical Data:

- Material of construction [MOC]:

Ductile Iron, Cast Iron, GGG40

- Size :

DN 50-DN 1000 (2” to 40”)

- Working Pressure :

DN 50 – DN 250 [10 bar], DN 300 – DN 400 [6 bar], DN 450 [5 bar], DN 500 – DN 600 [4 bar], DN 700 – DN 1000 [2 bar]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-MDP model is Pneumatic operated Knife Edge gate valve which can be offered in both UNIDIRECTIONAL & BIDIRECTIONAL type. This model is manufactured in Ductile Iron, Cast Iron, GGG40 materials in semi lug type. The model HE-MDP is designed according to MSS-SP-81 for various industrial applications.

The Pneumatic Knife Gate valves can also be provided along with accessories as per site requirement like: Limit switch, Air filter regulator, Solenoid valve, Connection tubing [PU, Stainless steel], Manual override.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Waste water treatments, Bulk handling, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

Model: HE-ME

Technical Data:

- Material of construction [MOC]:

WCB, CF8, CF8M, Ductile Iron

- Size :

DN 50-DN 1600 (2” to 64”) – Higher sizes on request

- Working Pressure :

DN 50 – DN 250 [10 bar], DN 300 – DN 400 & [6 bar], DN 450 [5 bar], DN 500 – DN 600 [4 bar], DN 700 – DN 1600 [2 bar]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-ME model is Electrical Actuator operated Knife Edge gate valve which can be offered in both UNIDIRECTIONAL & BIDIRECTIONAL type. This model is manufactured in WCB, CF8, CF8M, Ductile Iron materials in Full lug type. The model HE-ME is designed according to MSS-SP-81 for various industrial applications.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Waste water treatments, Bulk handling, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

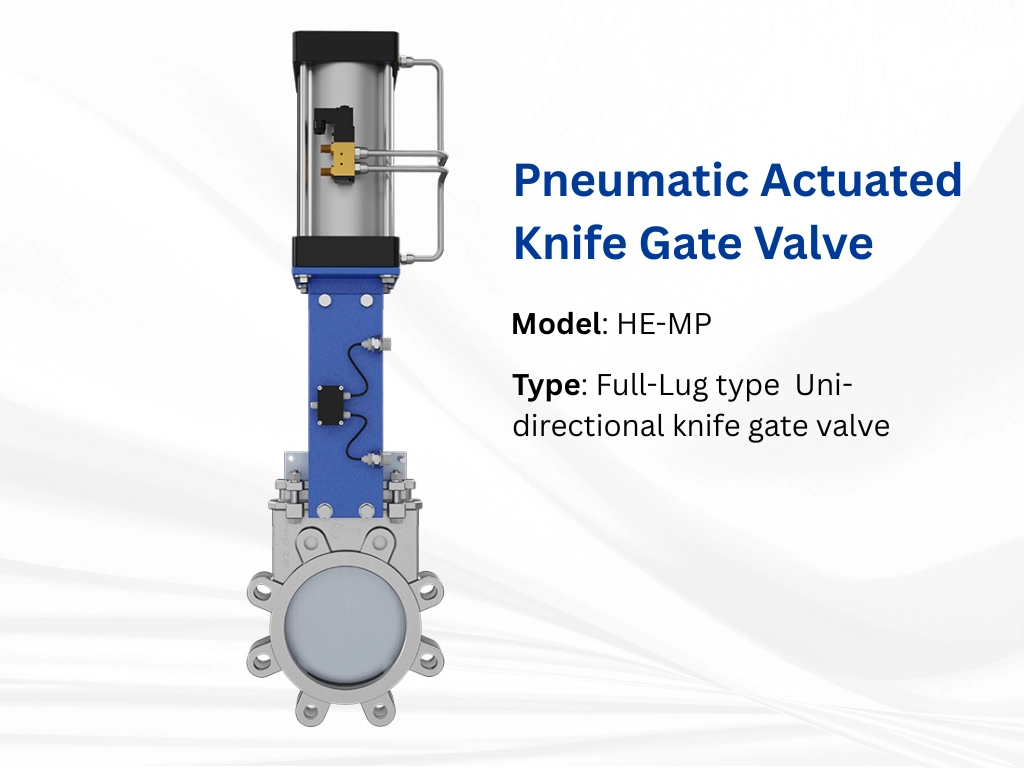

Model: HE-MP

Technical Data:

- Material of construction [MOC]:

WCB, CF8, CF8M, Ductile Iron

- Size :

DN 50-DN 1600 (2” to 64”) – Higher sizes on request

- Working Pressure :

DN 50 – DN 250 [10 bar], DN 300 – DN 400 & [6 bar], DN 450 [5 bar], DN 500 – DN 600 [4 bar], DN 700 – DN 1600 [2 bar]

- Standard Flange Connection :

DIN PN10 & ANSI B16.5 (150#) and Table “E” & “D”. PN6 / PN16 / PN25 / ANSI 125 (Other flange connections also available)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING’s HE-MP model is Pneumatic operated Knife Edge gate valve which can be offered in both UNIDIRECTIONAL & BIDIRECTIONAL type. This model is manufactured in WCB, CF8, CF8M materials in Full lug type. The model HE-MP is designed according to MSS-SP-81 for various industrial applications.

The Pneumatic Knife Gate valves can also be provided along with accessories as per site requirement like: Limit switch, Air filter regulator, Solenoid valve, Connection tubing [PU, Stainless steel], Manual override.

This model has proven design that assures non clogging shut off on suspended solids in various industries such as: Pulp & paper, Waste water treatments, Bulk handling, Food & beverages, Mining & steel plants, Oil & Gas, Chemical plant.

FAQs (Frequently asked questions)

Find detailed answers to common questions about Unidirectional Knife Gate valve in our Knowledge centre.

A uni directional knife gate valve is a type of valve which allows flow only in one direction – so as the name uni directional.

When the uni directional knife gate valve is installed in correct way, the fluid pushes the gate (closed condition) to create a perfect sealing.

It is an ideal valve choice for those applications where backflow prevention is necessary.