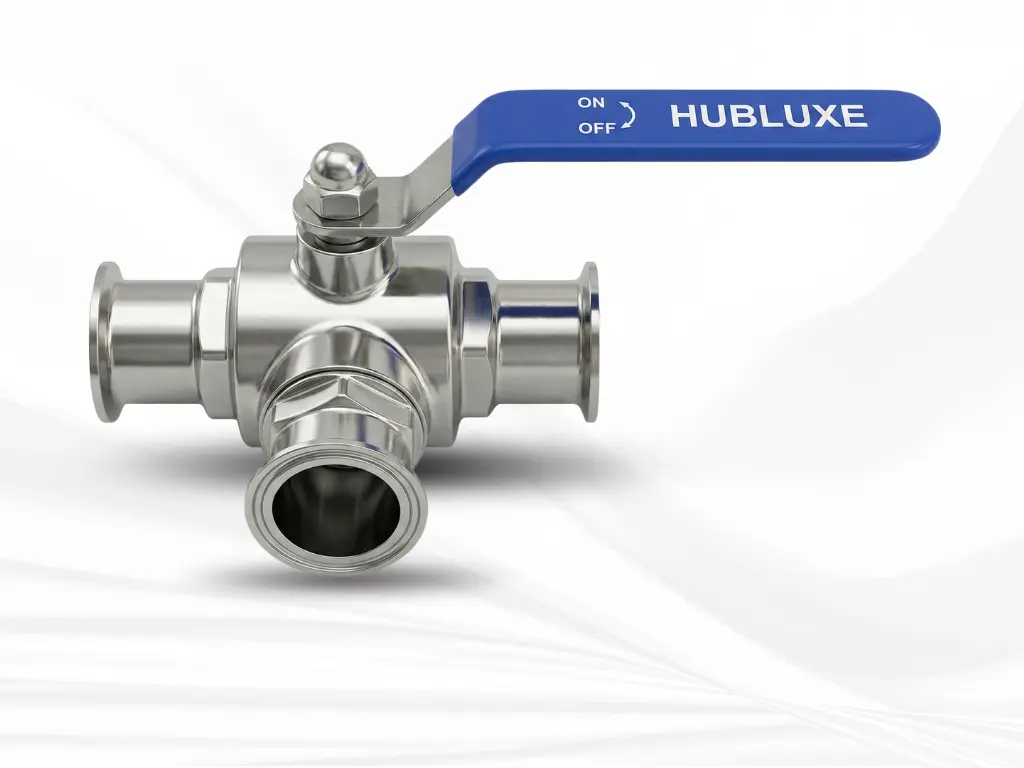

Tri Clover Sanitary Ball Valve Manufacturer (SS304 / SS316)

Key features:

Hubluxe Tri clover Sanitary Ball Valve manufactured from low-ferrite AISI 304 or 316L stainless steel for excellent corrosion resistance, durability, and long service life

Full-bore cavity design with no dead angles, ensures zero product retention and superior cleanability

Sanitary Tri-Clamp end connections provide quick installation, easy dismantling, and leak-free hygienic joints

Equipped with TFM / PTFE seats and seals to prevent product contamination and ensure reliable, long-term performance

Manual handle, pneumatic actuator, and electric actuator are fully interchangeable, offering flexibility for automation

Suitable for low to medium viscosity fluids, making it ideal for food, beverage, pharmaceutical, biotech, and cosmetic industries

- 100% fully tested to ensure leak-tight performance and reliability

Contact us today for Tri-Clover Sanitary Ball Valves (2-Way & 3-Way) solution.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Hubluxe Engineering manufactures Sanitary Ball Valve in compliant with global standards, offering most comprehensive range for bio-pharmaceuticals, pharmaceuticals, food & beverages and other process industries.

Our valves are manufactured from highly durable stainless steel and corrosion-resistant alloys, ensuring smooth operation without the need for frequent cleaning or disinfection.

The valves are designed to eliminate crevices and dead spaces where contaminants can accumulate. They are equipped with sanitary seals and gaskets that ensure leak-tight performance and maintain optimal sanitary conditions.

Whether you require a standard Tri-Clover ball valve for ON-OFF isolation of sanitary process lines or 3-way sanitary ball valve for flow diversion, mixing, or switching between lines, we offer complete solution in this segment.

Tri-Clover Sanitary Ball Valves (2-Way & 3-Way) technical specifications:

Product: ‘HUBLUXE’ Tri-Clover Sanitary Ball Valves (2-Way & 3-Way)

Size: DN15 to DN100 (1/2” to 4”)

Material of construction (MOC): AISI 304 / AISI 316 / AISI 316L

End connections: Welded, Socket, Clamped, Flanged, Threaded for hygienic connection

Maximum working pressure: Up to 10 bar (145 psi)

Temperature: -200 Deg. C to 1800 Deg. C (-40 F to 3560 F)

Mode of operation: Lever operated / Pneumatic operated

The followings are Sanitary ball valve applications:

- Pharmaceuticals

- Food & beverages

Biotechnology

- Chemical processing

- Cosmetics & personal care

Tri-Clover Sanitary Ball Valves (2-Way & 3-Way)

Technical Data:

Size: DN15 – DN100 (1/2” to 4”)

Body Material: AISI 304 / 316L

Seal: Teflon PTFE

End Connection: Clamp End, Threaded end, Weld End

Maximum working pressure: Up to 10 bar (145 psi)

Temperature: -200 Deg. C to 1800 Deg. C (-40 F to 3560 F)

Mode of operation: Lever operated / Pneumatic Actuator operated

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Technical Data:

Size: DN15 – DN100 (1/2” to 4”)

Body Material: AISI 304 / 316L

Seal: Teflon PTFE

End Connection: Clamp End, Threaded end, Weld End

Maximum working pressure: Up to 10 bar (145 psi)

Temperature: -200 Deg. C to 1800 Deg. C (-40 F to 3560 F)

Mode of operation: Lever operated / Pneumatic Actuator operated

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

FAQs (Frequently asked questions)

Find detailed answers to common questions about Tri-Clover Sanitary Ball Valves (2-Way & 3-Way) in our Knowledge centre.

A sanitary ball valve is a specialized valves designed for hygienic applications in Food & beverages, pharmaceuticals, Biotechnology, cosmetic & personal care etc. The components are designed in high grade of stainless steel (AISI 304 / AISI 316), which prevents contamination or bacterial growth.

The primary purpose is to regulate the flow without contaminating the product.

The key difference is the “dead space.” Industrial valves have gaps where fluid can stagnate and bacteria can grow. Sanitary valves feature Cavity-Filled Seats that fill these gaps, ensuring no product residue is left behind.

They also feature Tri-Clamp (TC) ends for easy disassembly and cleaning.