T Type Strainer Manufacturer

Key features:

Low pressure drops: Engineered for efficient flow with minimal energy loss

Economical for larger capacity: Tee type strainers are widely adopted filtration solutions for large nominal bore & they are low-cost solutions for industrial applications

Install horizontal or vertical conveniently: T type strainer can be installed in both kind of setups i.e. horizontal or vertical

The tee type strainer design allows easy installation in pipeline which is easy to clean & maintain.

The valve can be offered with differential pressure tapping & drain connections as per requirements

Handle fluids at higher velocity: It is best suited for handling fluids at higher capacity

Quick access to strainer: Ideal for installation in large pipes where quick access to the strainer is required

Convenient operation: When installed in horizontally in pipeline the chamber cover can be taken out without draining fluids ensuring smooth flowing process

Contact Hubluxe Engineering today for a competitive quote on Industrial T strainer / Tee type strainer.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE ENGINEERING is recognized among the top T type strainer manufacturer in India, delivering quality and cost-effective strainers for industrial fluid handling systems.

As experienced T type strainer manufacturers in India, we design and manufacture strainers that ensure effective filtration, low pressure drop, and long service life. Our industrial T strainers are widely used in oil & gas, chemical, power, and process industries, meeting stringent quality and performance standards.

Experience the durability and efficiency of our Fabricated T Strainer, engineered for superior filtration performance in industrial piping systems.

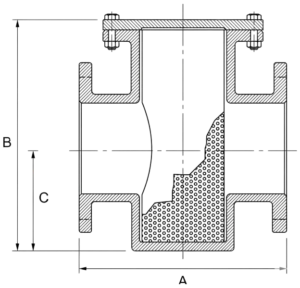

T type Strainer (Tee type strainer) technical specifications:

Product: ‘HUBLUXE’ T type strainer / Tee type strainer

Size: DN 25 to DN 600 (2” to 24”)

Pressure rating: ANSI 150#

Body Material of construction (MOC): Cast steel / SS 304 / SS316 / SS316 L

Strainer basket MOC: available in SS304, SS304L, SS316, SS316L

Mesh size: 5 microns to 500 microns

Manufacturing & Design Std.: ASME B16.34

End connections: ANSI B16.5, 150#

Applications: Cement plant, Power plant, Sugar industry, Paper & pulp industry, Chemical & fertilizer plants, Food & pharmaceuticals, HVAC system, Oil & gas

Other Strainer type:

As a leading industrial strainer manufacturer in India, we engineer high-performance, custom-fabricated filtration solutions designed to meet rigorous international standards like ASME and API for critical piping protection in global process industries including:

- Middle East & Eurasia (Oil & Gas): Saudi Arabia, UAE, Kuwait, Iran, Azerbaijan, Uzbekistan, and Russia.

- Africa (Mining & Processing): Nigeria, Ghana, Egypt, Tanzania, Morocco, Zambia, Kenya, South Africa, and Botswana.

- Asia Pacific (Infrastructure & Marine): Singapore, Indonesia, Thailand, Philippines, Cambodia, Vietnam, Malaysia, and Australia.

- South Asia: Nepal and Bhutan.

Standard construction details of T-type strainer

| Sr. no. | Description | Material |

|---|---|---|

| 1 | Body | IS210 Gr. FG200 / WCB / SS304 / SS316 |

| 2 | Screen | SS (AISI 304 / 316) |

| 3 | Gasket | Natural rubber / CAF |

| 4 | Stud & Nut | Natural rubber / CAF |

Test Pressure details:

- Hydro Test Pressure details:

- Body: 225 psig (16 kg/cm2)

T type strainer / Tee type strainer applications:

- Water treatment plant

- Natural gas & Air application

- Steam lines application

- HVAC systems

- Oil & gas industries

- Chemical industries

- Fertilizer plant

- Energy & Power plant

- Sugar industries

- Pharmaceutical industries

FAQs (Frequently asked questions)

Find detailed answers to common questions about T (Tee) Type Strainer in our Knowledge centre.

A T type strainer also sometimes known as Tee type is a kind of strainer designed to filter out unwanted materials, debris and solid particles from fluid system.

The tee type strainer resembles letter “T” which is why the name T type strainer.

The strainer is designed in T shape; flanges part is installed in horizontal direction while filter elements fit vertically from top.

A t type strainer can be installed vertically as well as horizontally as per the application requirements.