Swing Check Valve Manufacturer for Backflow Prevention

Key features:

Robust construction – materials available in Cast Iron (CI), Ductile Iron (DI), WCB, SS304 / SS316 / WC6 / WC9

Hubluxe make Swing check valve (Non return valve) – engineered for horizontal and vertical installations (upward flow direction)

It is designed for backflow prevention protecting equipment like pumps, compressor and process equipment

The valve is self-operated; no actuation required making it cost effective

Wide material selection options based on media & operating condition

Contact Hubluxe Engineering today for a competitive quote.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Hubluxe Engineering is renowned industrial swing check valve manufacturer, designed for the demanding applications.

Whether you require a Bolted Bonnet Swing Check Valve or a Swing Type Non-Return Valve, HUBLUXE is dedicated to delivering superior quality products backed by reliable performance and prompt customer support at every stage. Our swing check valves are designed to install in both direction horizontal or vertical installation (upward flow direction).

Controlled Closure: All the Valves feature a precision-machined hinge pin and disc assembly to ensure smooth, non-slam closure, protecting your piping system from destructive Water Hammer.

Hubluxe valves are engineered to BS 1868 and API 6D standards, offering a full-port design that minimizes turbulence and pressure loss. Featuring a Bolted Cover for easy in-line maintenance and Renewable Seat Rings, our valves ensure a long service life even in high-velocity steam, oil, and gas applications.

Swing Check Valve technical specifications:

Technical data:

Product: ‘HUBLUXE’ Swing Check Valve

Size Range: DN40 – DN600 (1 ½” – 24”)

Construction detail: Bolted cover, Swing check, Non slam check

Body Materials: Cast Iron (CI), Ductile Iron (DI), WCB, SS304 / SS316 / WC6 / WC9

Disc & seat: AISI 410 / AISI 304 / 316 / 304L / 316L / Stellite

End Connection: Flanged, Butt-Weld

Hinge Pin: AISI 410 / AISI 304 / 316 / 304L / 316L

Pressure rating: 150# to 600#

Manufacturing & dimension Standards:

- Design & manufacturing standard: API 6D / BS 1868

- Wall thickness: ANSI B16.34

- Pressure class: 150#, 300#, 600#

- Testing & inspection standard: API 598 / API 6D

- Face to face standard: ANSI B16.10

- End connection: Flange end as per ANSI B16.5 – 150#

- Pressure / Temperature Rating: ASME B 16.34

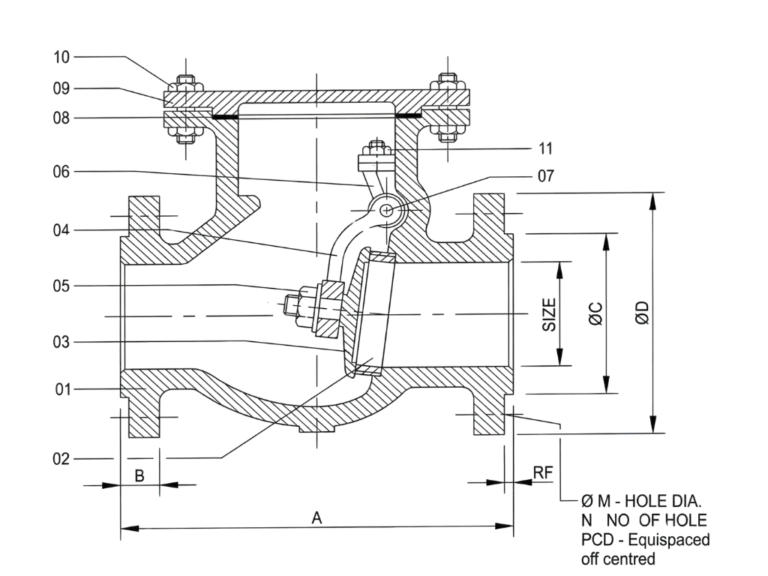

Swing Check Valve construction details:

| Sr. No. | Part Name | Material |

|---|---|---|

| 1 | Body | IS210 Gr. FG200/220/260 / Ductile Iron (DI) / WCB / SS304 / SS316 / WC6 / WC9 |

| 2 | Seat Ring | AISI 410 / AISI 304 / 316 / 304L / 316L / Stellite |

| 3 | Disc | AISI 410 / AISI 304 / 316 / 304L / 316L / Stellite |

| 4 | Hinge | WCB / CF8 / CF8M / CF3 / CF3M |

| 5 | Disc Nut | CS / 2H / SS 304 / SS 316 / SS 304L / SS 316L |

| 6 | Bracket | WCB / CF8 / CF8M / CF3 / CF3M |

| 7 | Hinge Pin | AISI 410 / AISI 304 / 316 / 304L / 316L |

| 8 | Gasket | CAF / PTFE / SPIRAL WOUND / GRAFOIL |

| 9 | Cover | IS210 Gr. FG200/220/260 / Ductile Iron (DI) / WCB / SS304 / SS316 / WC6 / WC9 |

| 10 | Cover Stud & Nut | ASTM A193 Gr. B7 / ASTM A194 Gr. 2H |

| 11 | Bracket Stud/Nut | CS / B7 / 2H / SS304 / 316 / 304L / 316L |

| Class | Hydro test pressure details | Service rating | ||

|---|---|---|---|---|

| Body | Seat | Pressure | Temperature | |

| 150 | 425 psig | 300 psig | 150 psig | 500° F |

| 300 | 1100 psig | 800 psig | 300 psig | 800° F |

| 600 | 2175 psig | 1600 psig | 600 psig | 800° F |

Swing check valve application:

- Oil & gas

- Petrochemicals

- Power generation

- HVAC

- LNG

- Fertilisers

- Steel & Mining

- Sugar Mills

- Food & Beverages

- Pharmaceuticals

FAQs (Frequently asked questions)

Find detailed answers to common questions about Swing Check valve in our Knowledge centre.

A swing check valve is a non return valve that uses a hinged disc that opens to allow forward flow and closes automatically to prevent reverse flow.

Swing check valves offer lower resistance to forward flow compared to lift check valves and are ideal for horizontal line installations with steady flow. They are also generally easier to maintain due to their accessible internal design.