Refractory Lined Dampers (Up to 1250°C)

Key features:

- For 98% & 100% leak efficiency different sealing materials are offered as per requirement

- Best suited for extreme temperatures and insulation

- Cost effective-To combat high temperature, the use of specialised material was required. Use of refractory lined materials make it most cost-effective solution

- Ability to withstand 0.1 bar static pressure with blades closed at fan shut-off

- Elevated temperature construction of upto 1250 Deg. C

- Engineered for isolation / control of various media such as Hot Flue gases, hot Air, Blast furnace gases etc.

- The refractory-lined construction ensures superior resistance to high temperatures

Contact Hubluxe Engineering today for a competitive quote on Refractory Lined Damper.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Engineered for Flue Gas, WHRU, and Smelter Applications:

Hubluxe Engineering known for the best refractory lined damper valves manufacturer in India that produces comprehensive range of refractory lined dampers in sizes from 150 mm to 4000 mm. The refractory lined dampers are also referred as high temperature damper.

The refractory lined dampers are engineered to withstand high temperature, ensuring safe & efficient operations. The function is same as any standard dampers only the refractories materials are added that withstand temperature as high as 1000 degree. C.

Hubluxe Engineering manufactures high-performance Refractory Lined Dampers engineered for the world’s most demanding thermal environments. Designed for continuous operation up to 1250°C (2282°F), our dampers provide critical isolation in Sulfuric Acid Plants, Steel Blast Furnaces, and Waste Heat Recovery Units (WHRU).

Unlike standard fabrication, our proprietary lining process utilizes high-alumina castable refractories or insulating firebricks (IFB) anchored to a heavy-duty carbon steel shell. This composite design ensures zero structural deformation and superior abrasion resistance against high-velocity flue gases. Production Capability: 150mm to 4000mm (Custom larger sizes available). Export Markets: Serving EPC contractors across GCC, Southeast Asia, Europe, and the Americas.

The technical specifications for Refractory Lined Damper:

Product: ‘HUBLUXE’ Refractory Lined Damper

Size: 150 mm to 4000 mm (higher sizes on request)

Body Material of construction (MOC): IS2062+Refrcatory lining / ASTM A36+Refreactory lining, ASTM A516 Gr.70+ refractory lining (or as per customer needs)

Shape: Round, Square, Rectangular design

Design temperature: Upto 1250 Deg. C

Sealing efficiency: 100% leak proof [through body & stem] and 99.5% at downstream

Construction: Fabricated

Design: Customisable as per requirements

End connection: Double Flange

Operation: Manual, Hydraulic, Pneumatic & Electrical actuator operation

Media: Hot Air / Flue Gas etc.

Pressure rating: PN1 / ± 1 bar

Flange drilling: As per IS6392 /ASME B16.5 / ASME B16.47 / BS EN 1092-1/ Mfg. STD.

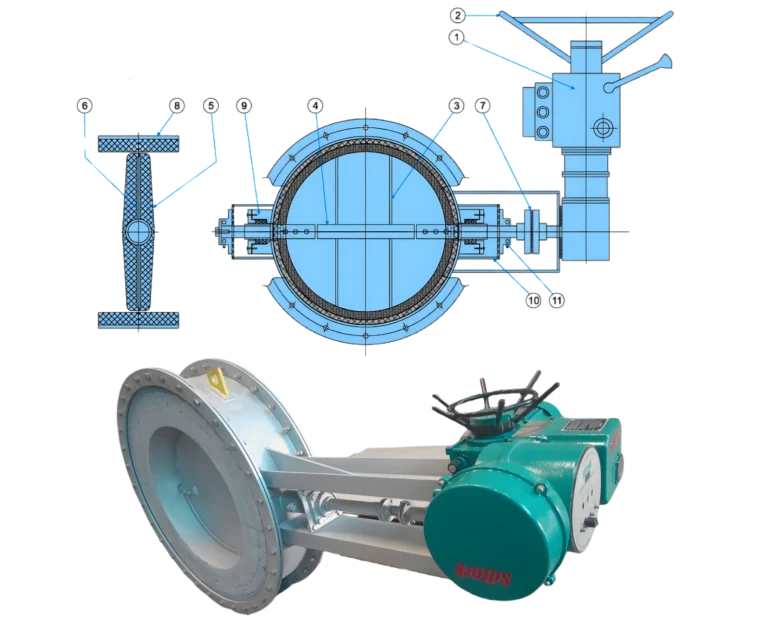

Standard construction features of Refractory Lined Damper

| Part No. | Description |

|---|---|

| 1 | Electrical Actuator |

| 2 | Hand Wheel |

| 3 | Flap with Stiffener |

| 4 | Stub Pipe |

| 5 | Heat 'K' Lining |

| 6 | Flap |

| 7 | Link assembly |

| 8 | Casing |

| 9 | Stuffing Box |

| 10 | Bracket for bearing |

| 11 | Bearing |

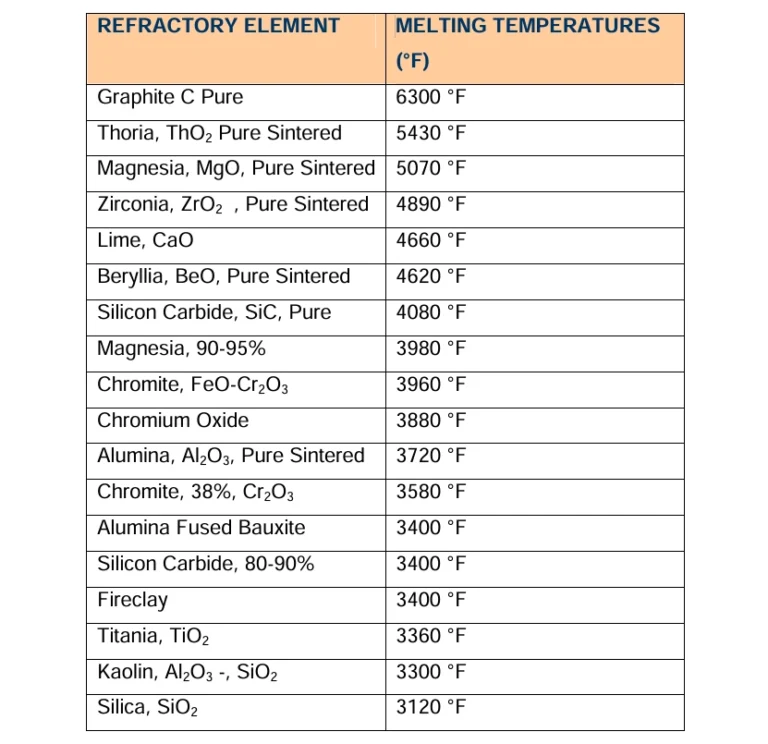

The common refractory materials used to construct refractory lined dampers are:

- High-alumina refractory – for high performance applications

- Fireclay refractory – Highly durable by making use of 50%-80% aluminium oxide

- Silica refractories – Excellent choice for high thermal loads because of their high melting points

- Ceramic fibers – Lightweight & excellent insulation option

- Lightweight bricks – Excellent option to withstand thermal shock as it is made from chamotte or mullite

- Zirconia – Best suited for ultra-high temperature often in the form of lightweight bricks or fibres

The HUBLUXE make Refractory Lined Damper valve is suitable for a wide range of industrial applications in:

- Blast Furnace Lines

- Exhaust System

- Mining & Mineral Processing

- Petrochemical

- Coke oven Gas isolation

- Glass Production

- Power Generation

- Metal Smelting

- Chemical Processing

FAQs (Frequently asked questions)

Find detailed answers to common questions about Refractory Lined Damper in our Knowledge centre.

It is a type of industrial damper having refractories materials between outer & inner casing of damper making them suitable to operate at extreme high temperatures. They are most suitable & essential in industries like smelter plant, power generation, hot flue gases, blast furnace where equipment is continuously exposed to intense heat.

Hubluxe Engineering is a prominent manufacturer & exporter, offers quality refractory lined dampers, engineered for extreme heat and trusted by major projects in the GCC, KSA, Southeast Asia (Malaysia, Indonesia, Thailand), and Australia.