Poppet Damper Manufacturer for High-Cycle Baghouse Isolation

Key features:

- Designed for quick cycling time and rapid actuation with drive options including pneumatic, electrical actuator for fast open-close cycles.

- Engineered to control the reverse gas flow, outlet flow and bypass flow of gases

- Economical shut-off capability for bag house applications

- Low leak or zero-leak configurations

- Durable and Corrosion-Resistant Construction of shafts in SS316 materials to ensure long term durability

Contact Hubluxe Engineering today for a competitive quote on Poppet damper.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Poppet dampers are multi directional airflow control system ideal for applications that requires quick cycling time and tight shut-off. Mostly used for bag house applications and incineration systems.

Robust engineering design that ensures reliable control over multi-directional gas flows—including reverse, outlet, and bypass streams, thus optimizing filtration efficiency, and reducing bag wears, making them a dependable solution for bag house applications.

In Bag Filter and Incinerator systems, dampers must cycle thousands of times per day to control back-flushing or process switching. Standard butterfly dampers often fail due to seal wear and actuator fatigue under this high-frequency stress.

Hubluxe Engineering’s Poppet Dampers utilize a Linear Vertical Action rather than rotation. This eliminates rotary friction on the seal, allowing for ultra-fast cycling (under 5 seconds) and extended seal life. Engineered for Zero Leakage, they act as the critical ‘heartbeat’ of your reverse-air cleaning system.

The Baghouse Standard: Unlike Guillotines (used for maintenance) or Multilouvers (used for modulation), our Poppet Dampers are purpose-built for Pulse Jet and Reverse Air applications where speed and repeatability are non-negotiable.

The technical specifications for Poppet damper:

Product: ‘HUBLUXE’ Poppet damper

Size: 300 mm to 3000 mm (higher size on request)

Body Material of construction (MOC): MS fabricated (IS 2062 GR. B) / SS 304 / SS 316 (other materials on request)

Construction: Fabricated construction

Types: Two-way design, Three-way design

Design: Customisable as per your requirements

End connections: Double Flanged end, Butt weld end

Operation: Manual, Hydraulic, Pneumatic & Electric actuator operation

Temperature suitability: -30 deg. C to 900 Deg. C

Pressure: ± 1 bar / PN1

Media: Air / Flue gas

Sealing efficiency: 100% leakproof [through body & stem] & 99.5% at downstream

Leakage class: 0, I, II, III & IV CAN BE OFFERED AS PER ASME AG-1

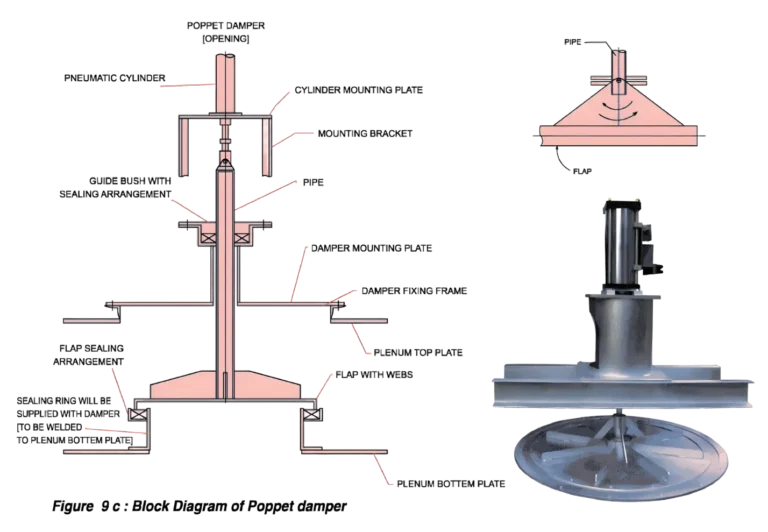

Standard construction details of Poppet Damper

A poppet damper is a specialized type of isolation valve, primarily used in industrial air handling systems like fabric filter dust collectors (often called baghouses).

The poppet plate is pivoted at one end to the floor of an inlet manifold and has a pair of gas straightening vanes attached to its underside.

One of the vanes is near to the pivoted end and other is parallel to the poppet plate and has lead-in and exit portions which gently turn the gas about 900 degrees.

To direct the gases to a plurality of collectors a damper is preferably provided with the angles of the various poppet plates being individually adjustable so as to divide the flow in any proportion desired. Refer the figure above.

Why Choose HUBLUXE as a Poppet Damper Manufacturer

As a leading Industrial damper supplier, HUBLUXE Engineering specializes in high-performance isolation solutions for critical industrial air systems. Every Damper we produce is engineered for the demanding requirements of high-cycle baghouse isolation, providing absolute zero-leakage performance during pulse-jet cleaning cycles. By choosing a specialized Damper Manufacturer, you ensure that your dust collection system maintains 100% chamber isolation, maximizing filtration efficiency and system longevity.

The HUBLUXE make Poppet Damper valve is suitable for a wide range of industrial applications. Due to their efficient flow control and isolation feature they are most widely used in:

- Baghouse for controlling the reverse gas flow, outlet flow and bypass flow

- Oil & Gas

- Power Generation

- Thermal oxidizer systems

- Chemical Industries

- Diversion of Flowing media or any process that requires isolation

FAQs (Frequently asked questions)

Find detailed answers to common questions about Poppet Damper in our Knowledge centre.

A poppet damper in HVAC is used to control the flow of air or gases. It has disc shaped or cone shaped valve (often called as poppet) which then operates by moving in vertical direction to control or shut-off the flow.