Goggle Valves for Absolute Gas Isolation

Key features:

- Dismantling of bonnets as an option

- Movable seat ring with expansion bellow

- The enclosed device system ensures hazardous gases from escaping into the environment

- Manual operation available in case of power failure

- Replaceable seat option

- Jam-proof operation

- Valve mounting can be at any altitude

- Replaceable Hydraulic cylinders and tubing without interrupting any operation

Contact Hubluxe Engineering today for a competitive quote.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

In Blast Furnace and Toxic Gas applications, a simple shut-off is not enough. Maintenance teams working downstream need visual certainty that the line is physically broken.

Hubluxe Engineering’s Goggle Valves (also known as Spectacle Blinds) provide 100% positive isolation. Whether using our Fully Enclosed design to prevent hazardous gas release or the Open Type for standard service, our clamping mechanism ensures a gas-tight seal that allows personnel to enter ducts safely.

Critical Safety Feature: The valve can be designed to operate on Hydraulic and Electric Actuator that are engineered for Man-Safe Isolation. The heavy-duty body remains rigid even during the declamping cycle, preventing pipeline stress from distorting the seal face.

Technical specifications:

Product: ‘HUBLUXE’ Man-Safe Isolation Goggle Valve

Size: 200 mm to 3500 mm

Body Material of construction (MOC): MS fabricated (IS 2062 GR. B) / SS 304 / SS 316 (other special materials on request)

Valve Design: Bi-Directional

Type of sealing: Resilient sealing

Orientation: Vertical in Horizontal pipeline, Horizontal in vertical pipeline, Inclined

Testing: Body test, Seat test, Operational test

Operation: Electrical actuator, Pneumatic actuator, Hydraulic actuator, Manual gear box

Make / Brand: Hubluxe

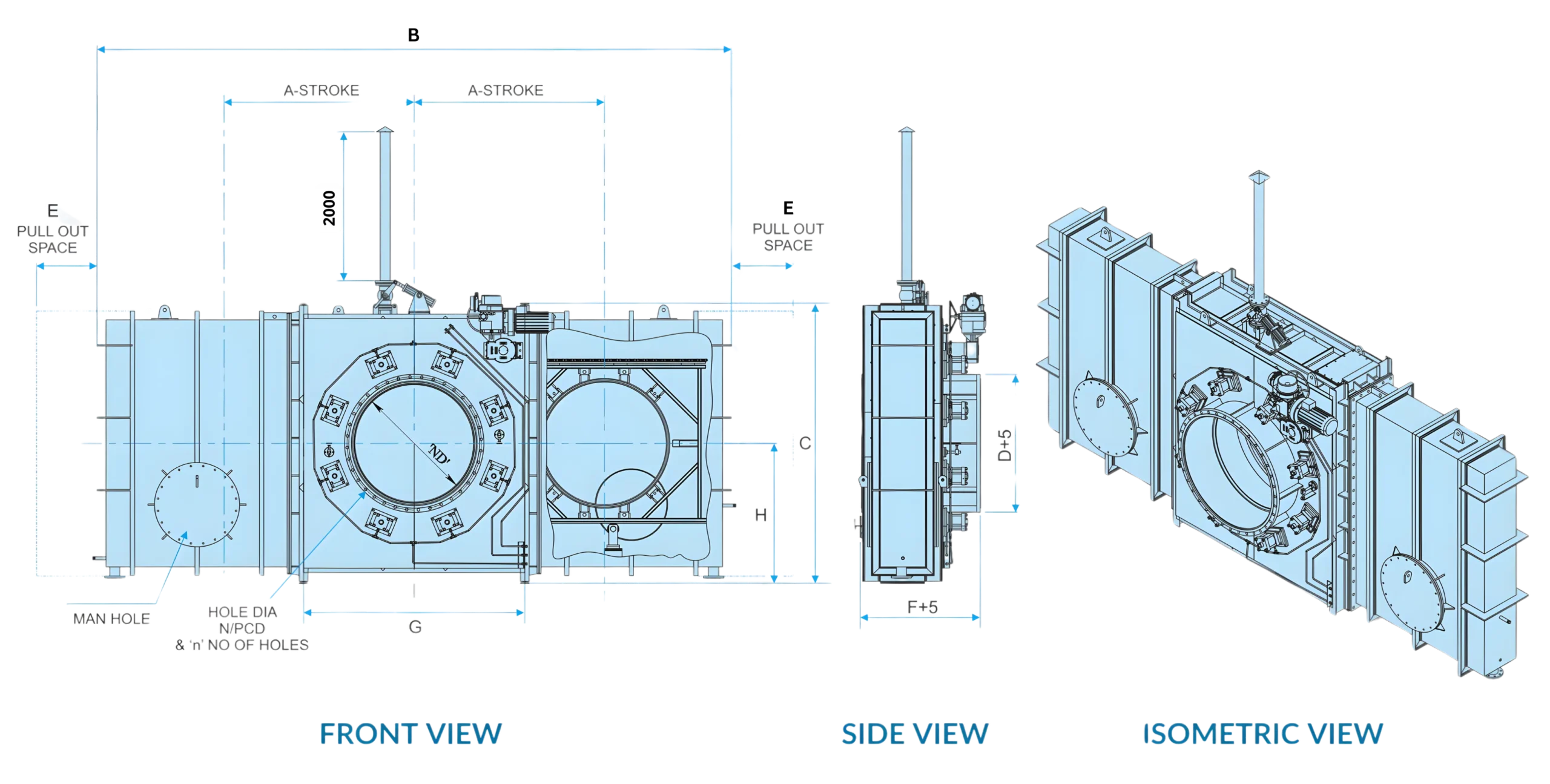

Drawing & approx dimensional table:

| # | ND | Flange OD-D | Face to Face Dim-F | Hole Dia. N/PCD | No. of Holes-N | B | C | E | G | H | Approx Wt. in Kg |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 600 | 755 | 1000 | 26/705 | 20 | 3600 | 1775 | 500 | 1500 | 900 | 4500 |

| 2 | 900 | 1075 | 1200 | 30/1120 | 28 | 5060 | 2255 | 775 | 1700 | 1140 | 6800 |

| 3 | 1000 | 1175 | 1200 | 30/1120 | 28 | 5650 | 2550 | 825 | 2000 | 1290 | 7500 |

| 4 | 1300 | 1520 | 1350 | 36/1450 | 36 | 6800 | 2880 | 1200 | 2300 | 1445 | 10500 |

| 5 | 1400 | 1572 | 1350 | 36/1560 | 36 | 7000 | 3200 | 1250 | 2500 | 1675 | 11000 |

| 6 | 1600 | 1830 | 1350 | 36/1760 | 40 | 8000 | 3325 | 1300 | 2700 | 1600 | 13500 |

| 7 | 1700 | 1935 | 1350 | 39/1865 | 44 | 8500 | 3425 | 1300 | 2800 | 1650 | 14500 |

| 8 | 2000 | 2265 | 1350 | 45/2180 | 48 | 10000 | 4029 | 1550 | 3300 | 1950 | 22500 |

| 9 | 2500 | 2705 | 1600 | 45/2640 | 60 | 10800 | 4650 | 1675 | 3660 | 2216 | 24500 |

| 10 | 2800 | 3030 | 2000 | 51/2960 | 64 | 11210 | 5110 | 1775 | 3800 | 2510 | 31500 |

| 11 | 3000 | 3245 | 2000 | 59/3170 | 68 | 12010 | 5475 | 1900 | 4070 | 2690 | 33750 |

Note:

1. Other sizes on demand

2. All dimensions are tentative (only for reference)

3. All dimensions are in mm

Maintenance and support:

For maintenance and servicing we offer quick support and assistance with in house experienced technicians. We also maintain a minimum stock of maintenance spares all the time.

Applications:

- Oil & gas

- Coke oven gas

- Blast furnace

- Steel & Mining

- Thermal power plants

- Sugar Mills

- Food & Beverages

- Pharmaceuticals

Absolute Gas Isolation Valve:

This type of valve applications are commonly found in steel plants, power stations, refineries, and gas processing facilities, where they isolate sections of pipe handling Oil & gases.

FAQs (Frequently asked questions)

Find detailed answers to common questions about Goggle Valves in our Knowledge centre.

A goggle valve is large diameter isolation valve sometimes also known as “100% man shutoff valve”. The goggle valve is primarily used in low pressure gas lines for handling toxic or blast furnace gases.

A Goggle Valve is used to safely isolate sections of pipeline in industrial systems, especially in Oil & gas industries – having low pressure gas lines that carries toxic or blast furnace gases.

The main purpose is to provide positive isolation, ensuring that maintenance teams can safely enter or work on downstream ducts or equipment without any risk of toxic or combustible gases entering the area.

This creates a fully “man-safe” environment.

Goggle Valves are widely used in critical areas of steel plants, refineries, coke oven gas lines, and other heavy industrial applications where complete shut-off is required.

The leading goggle valve manufacturers are few, since goggle valves operate in the most critical sections of a plant, their manufacturing process requires robust engineering, validated designs that guarantees 100% leak-proof performance. These valves must deliver a complete shutoff making it safe for carrying out maintenance work.

Hubluxe Engineering manufactures goggle valves on proven design standards, offering reliable, high-quality, and cost-effective solutions.