Globe Valve Manufacturer & Exporter (API 600 / API 602)

Key features:

Throttling Efficiency: Optimized disc design ensures accurate flow regulation with minimal turbulence.

Robust Seating: Stellite-faced seat and disc provide superior resistance to wear, galling, and high-temperature erosion.

Valve Operation: Available in Handwheel, Gear Operated, or Actuated (Pneumatic/Electric) configurations for automated control.

Seal Integrity: Deep stuffing box design with graphite packing ensures fugitive emission compliance.

Back Seat Arrangement: Allows for repacking of the valve under pressure (when fully open).

Contact Hubluxe Engineering today for a competitive quote on Globe Valves.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

As a specialized Globe Valve manufacturer, Hubluxe Engineering delivers high-performance valves engineered specifically for efficient throttling and frequent operation duties. Unlike gate valves, our Globe Valves are designed with a spherical body and a movable plug-disc, allowing for precise regulation of flow in critical pipelines.

Whether your application requires API 602 Forged Steel valves for high-pressure steam or BS 1873 Cast Steel valves for refinery isolation, Hubluxe ensures zero-leakage performance. Our valves feature a robust rising stem design and hardened seating surfaces (Stellite) to resist erosion, making them the ideal choice for Oil & Gas, Power Generation, and Petrochemical industries where flow modulation is essential.

With proven engineering expertise, HUBLUXE has established itself as a trusted globe valve manufacturer as well as globe valve exporter for industrial applications.

Globe Valve technical specifications:

Product: ‘HUBLUXE’ Globe valve

Size: DN 50 – DN 600 (2” – 24”)

Body Material of construction (MOC): ASTM A216 Gr. WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9

- Bonnet: ASTM A216 Gr. WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9

End connections: RF Flange end (ASME B16.5), Butt weld end (ASME B16.25)

- Pressure class: 150#, 300#, 600#

- Design & manufacturing standard: BS 1873

Testing & inspection standard: API 598

Face to face standard: As per ANSI B16.10

Shell wall thickness: ANSI B16.34

- Operation: Manual, Pneumatic, Electrical actuator, Bare shaft, Gearbox operated with Manual override

Hubluxe has established itself as a leading globe valve exporter, supplying API-certified flow regulation solutions to major oil and gas projects across the Middle East, Europe, and Southeast Asia.

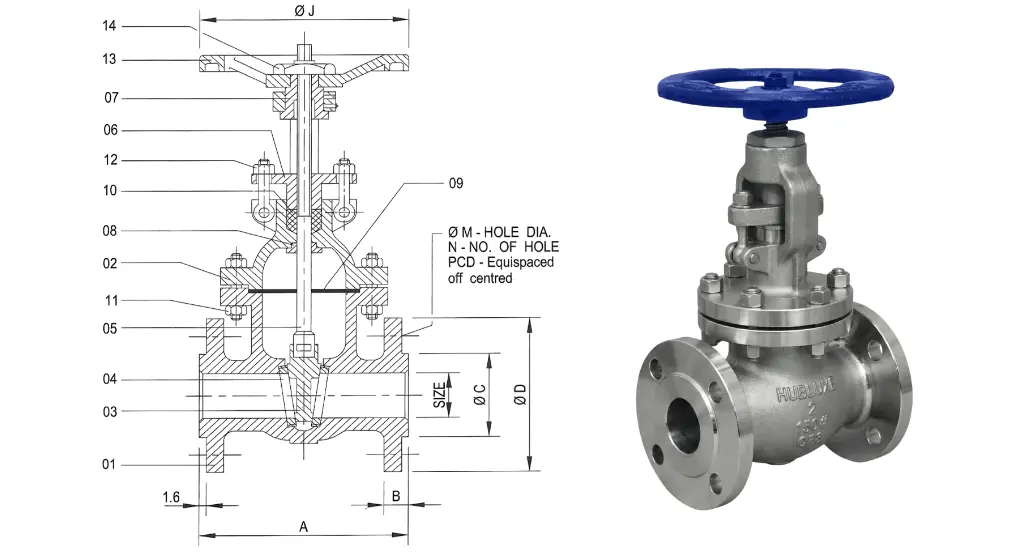

Standard construction details of Globe valve:

| Sr. No. | Part Name | Material |

|---|---|---|

| 1 | Body | DI / WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9 |

| 2 | Bonnet | DI / WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9 |

| 3 | Seat Ring | 13% Cr. steel / AISI 304 / AISI 316 / AISI 2205 (Duplex) |

| 4 | Disc | 13% Cr. steel / AISI 304 / AISI 316 / AISI 2205 (Duplex) |

| 5 | Stem | 13% Cr. steel / AISI 304 / AISI 316 / AISI 2205 (Duplex) |

| 6 | Disc Nut | 13% Cr. steel / AISI 304 / AISI 316 / AISI 2205 (Duplex) |

| 7 | Back seat bush | AISI 410 / AISI 304 / AISI 316 |

| 8 | Gland bush | AISI 410 / AISI 304 / AISI 316 |

| 9 | Gland flange | Carbon steel / Stainless steel |

| 10 | Gland Packing | Grafoil / PTFE Impreg. asbestos / Metallic wire reinforced |

| 11 | Yoke Sleeve | Al. Bronze / Ni-Resist |

| 12 | Bonnet Gasket | CAF / Spiral wound / PTFE |

| 13 | Bonnet stud & nut | ASTM A193 Gr. B7 / ASTM A194 Gr. 2H / Stainless steel |

| 14 | Bonnet bolt & Nut | CS / ASTM A193 Gr. B7 / ASTM A194 Gr. 2H / Stainless steel |

| 15 | Hand wheel | MS / SG IRON |

| 16 | Hand wheel nut | CS / SS304 / SS316 / SG Iron |

The followings are Globe valve applications:

- Oil & gas

- Petrochemicals

- Power generation

- HVAC

- LNG

- Chemical industries

- Fire systems

- Fertilisers

- Steel & Mining

- Sugar Mills

- Food & Beverages

- Pharmaceuticals

- Water treatment plants

- Muncipal corporation

FAQs (Frequently asked questions)

Find detailed answers to common questions about Globe Valve in our Knowledge centre.

A Gate Valve is designed for isolation (fully open or fully closed), while a Globe Valve is designed for throttling (regulating the flow volume).

The Technical Detail:

Flow Path: In a Gate Valve, fluid flows straight through with minimal resistance. In a Globe Valve, the flow changes direction (Z-shape), passing up and over the seat. This design creates higher pressure drop but allows for precise control.

Wear Resistance: If you try to throttle with a Gate Valve, the high-velocity fluid will erode the disc (wire drawing). Globe Valves are built with stellite-faced trims specifically to withstand this erosion during partial opening.

Yes, they can. While their primary strength is throttling, Hubluxe Cast Steel Globe Valves provide excellent shut-off capabilities. In fact, due to the pressure on the disc helping to seal the valve, they often provide a tighter seal than gate valves in high-pressure steam applications. However, operators should be aware of the higher pressure drop compared to gate valves.