Gate Valve Manufacturer & Exporter (API 600 / API 602)

Key features:

With a simple, robust design, these valves deliver reliable performance in high‑pressure applications; however, they are not recommended where precise flow control is required.

Integral Yoke & Bonnet Design: Features an integral yoke and bonnet with outside screw and yoke configuration, complemented by a bolted bonnet for enhanced performance and easy maintenance.

OS & Y Construction: Outside screw and yoke (OS & Y) design ensures durability, easy maintenance, and reliable performance in demanding applications.

Flexible Wedge Options: Available with solid or split wedge configurations, the flexible wedge design provides superior sealing and compensates for thermal or pressure‑induced body deformation.

High‑Pressure Bonnet Options: Pressure seal bonnet or welded bonnet available on request, designed to withstand high‑pressure environments with enhanced safety and performance.

Contact Hubluxe Engineering today for a competitive quote on Gate valve.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Gate Valve Manufacturer for Industrial Flow Isolation

As a leading Gate Valve manufacturer in India, Hubluxe Engineering specializes in heavy-duty Industrial Isolation Valves designed for zero-leakage performance. Our range features the robust OS&Y Gate Valve (Rising Stem) design, ensuring clear visual indication of open/closed status for operator safety.

Our comprehensive range includes Cast Steel Gate Valves (API 600) and Forged Steel Gate Valves (API 602) designed for critical service in oil, gas, petrochemical, and power generation sectors. Available in material grades such as ASTM A216 WCB, A351 CF8/CF8M, and Forged A105, our valves ensure maximum durability in high-pressure and high-temperature environments.

HUBLUXE is an industrial gate valve manufacturer delivering reliable isolation valves for oil & gas, power, and industrial process applications. Whether you require a standard Sluice Valve for water or a high-pressure alloy steel unit, our valves deliver unmatched durability. With proven manufacturing expertise, HUBLUXE has established itself as a trusted gate valve manufacturer for domestic and export markets.

Gate valve technical specifications:

Product: ‘HUBLUXE’ Gate valve

- Design types: OS&Y (outside screw & yoke) construction / Flexible wedge / Full port / Pressure seal bonnet / Welded bonnet

Size: DN 25 – DN 600 (1” – 24”)

Body Material of construction (MOC): ASTM A216 Gr. WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9

- Bonnet: ASTM A216 Gr. WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9

Wedge: ASTM A216 Gr. WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9 / CA15

Type of seat: Renewable Seat

End connections: RF Flange end (ASME B16.5), Butt weld end (ASME B16.25)

- Pressure class: 150#, 300#, 600#

Design & manufacturing standard: API 600

Testing & inspection standard: API 598

Face to face standard: As per ANSI B16.10

Shell wall thickness: ANSI B16.34

- Operation: Manual, Pneumatic, Electrical actuator, Bare shaft, Gearbox operated with Manual override

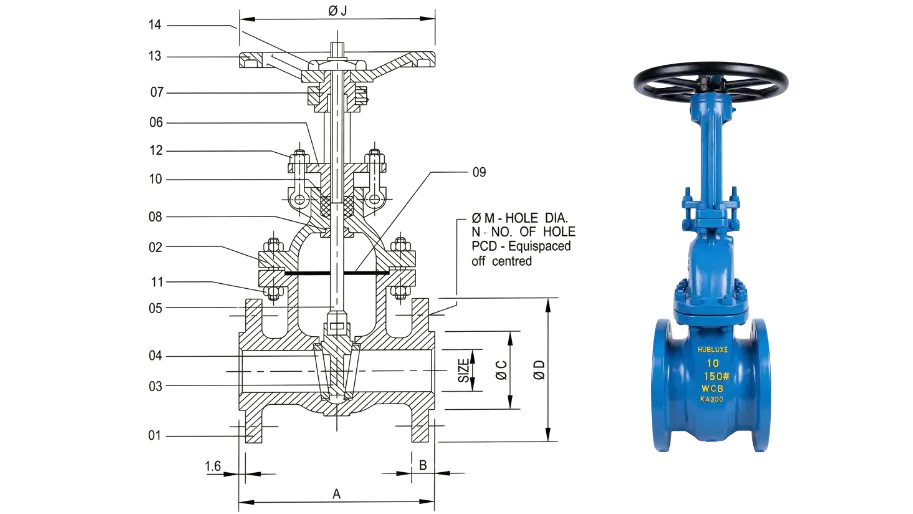

Standard construction details of Gate valve flange end:

| Sr. No. | Part Name | Material |

|---|---|---|

| 1 | Body | DI / WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9 |

| 2 | Bonnet | DI / WCB / CF8 / CF8M / CF3 / CF3M / WC6 / WC9 |

| 3 | Wedge | 13% Cr. steel / AISI 304 / AISI 316 / AISI 2205 (Duplex) |

| 4 | Seat Ring | 13% Cr. steel / AISI 304 / AISI 316 / AISI 2205 (Duplex) |

| 5 | Stem | 13% Cr. steel / AISI 304 / AISI 316 / AISI 2205 (Duplex) |

| 6 | Gland | Carbon steel / Stainless steel |

| 7 | Yoke Sleeve | Al. Bronze / Ni-Resist |

| 8 | Back seat bush | AISI 410 / AISI 304 / AISI 316 |

| 9 | Gasket | CAF / Spiral wound / PTFE |

| 10 | Gland Packing | Grafoil / PTFE Impreg. asbestos / Metallic wire reinforced |

| 11 | Bonnet stud & nut | ASTM A193 Gr. B7 / ASTM A194 Gr. 2H / Stainless steel |

| 12 | Bonnet bolt & Nut | CS / ASTM A193 Gr. B7 / ASTM A194 Gr. 2H / Stainless steel |

| 13 | Hand wheel | MS / SG IRON |

| 14 | Hand wheel nut | CS / SS304 / SS316 / SG Iron |

The followings are Gate valve applications:

Mechanism & Best Use Case of Gate valve: Linear motion, full bore, best for on/off and isolation applications suitable for Low pressure drop, bidirectional—but should not be used for throttling.

- Oil & gas

- Petrochemicals

- Power generation

- HVAC

- LNG

- Chemical industries

- Fire systems

- Fertilisers

- Steel & Mining

- Sugar Mills

- Food & Beverages

- Pharmaceuticals

- Water treatment plants

- Muncipal corporation

FAQs (Frequently asked questions)

Find detailed answers to common questions about Gate Valve in our Knowledge centre.

A gate valve is a type of isolation valve used to stop or start the flow of fluid in pipeline system. It consists of gate that either moves up or down to control the flow.

Ideal for those applications where Low pressure drop, bidirectional are required — but should not be used for throttling.