Forged Steel Globe Valve Manufacturer (800#)

Key features:

Engineered for accurate throttling & shut-off in high pressure and temperature environments

Welded & Renewable Seat Rings extends the service life

Available in straight pattern, Y type pattern, Bolted bonnet, weldable bonnet design, Pressure Seal Welded Bonnet on request for High Pressure

Hubluxe’s high pressure forged steel globe valves are manufactured according to BS 5352 / API 602 / ISO 15761 / ASME B16.34 design standards

Selection of wide range of materials from Carbon steel, Stainless steel, Duplex steel, Alloy & other special materials

- End connection to choose from Socket weld (SW), Screwed End (NPT / BSPT), Butt Weld (BW), Flange ends

Contact Hubluxe Engineering today for a competitive quote on Forged Globe valve 800.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Hubluxe is a trusted forged steel globe valve manufacturer delivering high-performance valves designed for precise flow control in high-pressure applications. Our forged steel globe valves are engineered using alloy and Forged carbon / steel materials to ensure durability, leak-proof operation, and long service life in different industrial environments.

These forged globe valves are manufactured in 800# class pressure ratings and are widely used across oil and gas, petrochemical, power generation, and refinery industries. All valves components are precision-machined to provide accurate throttling control, making them suitable for both on-off and regulating services. Each forged steel globe valve is manufactured in compliance with international standards such as API, ASME, and ASTM to meet global operational requirements.

As an experienced forged steel globe valve supplier, Hubluxe offers various end connections such as Flange end, Screwed End to BSP-F/NPT-F, Welded end, in various body materials, and trims to suit specific process conditions. Our valves are designed to withstand extreme temperatures and pressures while maintaining operational safety and efficiency. All API 602 forged globe Valves are quality tested to ensures reliable performance under critical service conditions.

Choose Hubluxe as API forged steel globe valve manufacturer that combine engineering excellence, robust construction, and consistent quality. Contact us today to receive technical support, detailed specifications, or a competitive quotation tailored to your project requirements.

Forged Steel Globe Valve technical specifications:

- Product: ‘HUBLUXE’ Forged Steel Globe Valve

Size: 15 mm – 50 mm (1/2” – 2”)

- Material of construction (MOC): Carbon Steel – A105, LF / Stainless steel – F304, F304L, F316, F316L / Duplex steel – F51, F53, F55

- Design options: OS & Y type, Welded bonnet, Pressure seal design

- End connection: Screwed End, Socket Weld End, Butt Weld End, Flange end

- Operation: Manual

- Design Standard: BS 5352, API 602, ISO 15761, ASME B16.34

Inspection & Testing standards: API 598

Pressure Class rating: ANSI 150#, 300#, 600#, 800#, 1500#, 2500#

Partnering with a specialized forged steel globe valve manufacturer ensures that your high-pressure piping systems maintain absolute structural integrity and precise throttling control in accordance with API 602 and ASME B16.34 standards

Hubluxe Engineering is a global supplier of A105 Forged Steel Globe Valve, delivering high-performance flow control solutions to major industrial hubs including:

- Middle East & Eurasia (Oil & Gas): Saudi Arabia, UAE, Kuwait, Iran, Azerbaijan, Uzbekistan, and Russia.

- Africa (Mining & Processing): Nigeria, Ghana, Egypt, Tanzania, Morocco, Zambia, Kenya, South Africa, and Botswana.

- Asia Pacific (Infrastructure & Marine): Singapore, Indonesia, Thailand, Philippines, Cambodia, Vietnam, Malaysia, and Australia.

- South Asia: Nepal and Bhutan.

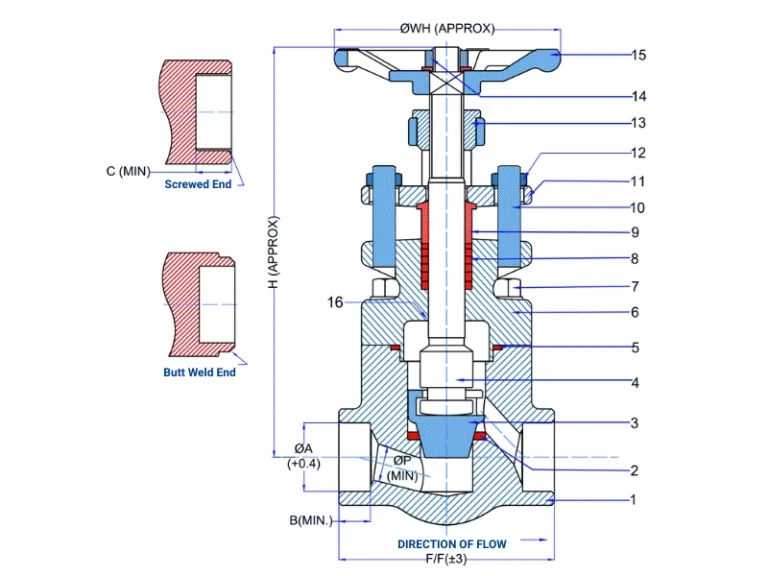

Forged Steel Globe valve SCREWED END parts list:

| Sr. No. | Parts | Materials |

|---|---|---|

| 1 | Body | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 2 | Seat Ring | ASTM A 182 GR. F6a / F304 / F304L / F316 / F316L |

| 3 | Plug | ASTM A 217 GR. CA-15 / CF8 / CF3 / CF8M / CF3M |

| 4 | Stem | ASTM A 182 GR. F6a / F304 / F304L / F316 / F316L |

| 5 | Gasket | SS-304 Spiral Wound Graphite |

| 6 | Bonnet | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 7 | Hex Bolt | ASTM A193 Gr. B7 / B8 / B8M |

| 8 | Gland Packing | Flexible graphite rings |

| 9 | Gland Bush | ASTM A 276 TYPE SS-410 / 304 / 304L / 316 / 316L |

| 10 | Stud | ASTM A193 Gr. B7 / B8 / B8M |

| 11 | Gland Flange | ASTM A 105 / F304 / F316 / F11 / F22 |

| 12 | Stud Nut | ASTM A 194 GR. 2H / B8 / B8M |

| 13 | Yoke Sleeve | BS970: 1955 EN1A |

| 14 | Stem Nut | ASTM A 194 GR. 2H / B8 / B8M |

| 15 | Hand Wheel | SG Iron / MI |

| 16 | Back Seat | Integral |

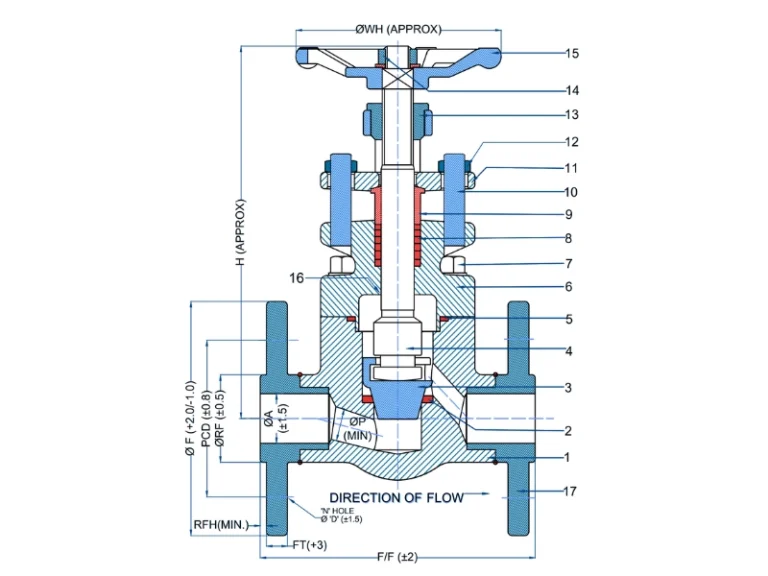

Forged Steel Globe valve FLANGE END parts list:

| Sr. No. | Parts | Materials |

|---|---|---|

| 1 | Body | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 2 | Seat Ring | ASTM A 182 GR. F6a / F304 / F304L / F316 / F316L |

| 3 | Plug | ASTM A 217 GR. CA-15 / CF8 / CF3 / CF8M / CF3M |

| 4 | Stem | ASTM A 182 GR. F6a / F304 / F304L / F316 / F316L |

| 5 | Gasket | SS-304 Spiral Wound Graphite |

| 6 | Bonnet | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 7 | Hex Bolt | ASTM A193 Gr. B7 / B8 / B8M |

| 8 | Gland Packing | Flexible graphite rings |

| 9 | Gland Bush | ASTM A 276 TYPE SS-410 / 304 / 304L / 316 / 316L |

| 10 | Stud | ASTM A193 Gr. B7 / B8 / B8M |

| 11 | Gland Flange | ASTM A 105 / F304 / F316 / F11 / F22 |

| 12 | Stud Nut | ASTM A 194 GR. 2H / B8 / B8M |

| 13 | Yoke Sleeve | BS970: 1955 EN1A |

| 14 | Stem Nut | ASTM A 194 GR. 2H / B8 / B8M |

| 15 | Hand Wheel | SG Iron / MI |

| 16 | Back Seat | Integral |

| 17 | Flange | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

Forged Steel Globe Valve applications:

- Nuclear & thermal power generation

- Cement Industries

- Iron & Steel Mills

- Water treatment

- Steam and condensate lines

- High-pressure utility systems

- Oil & Gas Industries

- Pharmaceutical industries

- Paper & pulp industries

- Petrochemcial Industries

- Thermal Power Plants

FAQs (Frequently asked questions)

Find detailed answers to common questions about Forged Steel Globe Valve in our Knowledge centre.

A forged steel globe valve is a linear motion valve designed for precise control flow in high pressure-temperature services. Unlike casting process, these valves are manufactured through forging process which offers excellent strength & durability.

The term forged steel refers to the manufacturing process in which steel is heated at high temperatures to shape them under high pressure. The resulting product is much denser, stronger material compared to cast steel.

As a specialized forged steel globe valve manufacturer, Hubluxe Engineering utilizes precision forging to eliminate the risk of porosity in high-pressure steam and liquid lines.