Forged Steel Gate Valve Manufacturer (API 602 & Class 800)

Key features:

Hubluxe’s Forged gate valves complies with API 602 & ASME B16.34 Standards

Our Forged Steel Gate Valves are designed for exceptional durability in high pressure-temperature service

Available in OS&Y bolted bonnet or welded bonnet

Renewable seat & disc

- Major applications in steam & mineral oil

- Other industries include: Boiler plant fuel line, Chemical industries, steam generation plant, HAVC systems etc.

Contact Hubluxe Engineering today for a competitive quote on Forged Steel Gate Valve.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

“Unmatched quality Forged Steel Gate valve from HUBLUXE”

Forged Steel Gate Valve technical specifications:

Product: ‘HUBLUXE’ Forged steel gate valve

Size: 15 mm to 50 mm (1/2” to 2”)

Design: OS & Y type, Renewable Seat Rings, Pressure Seal Welded Bonnet on request for High Pressure

Material of construction (MOC): (Carbon Steel – A105, LF2), (Alloy Steel – F5, F9, F11, F22, F91), (Stainless Steel – F304L, F316L), (Duplex Steel – F51, F53, F55)

End connection: Screwed End, Socket Weld End, Butt Weld End, Flange End

Operation: Manual

Pressure Rating / class: 600#, 800#, 1500#, 2500#

Design Standard: API 602, ISO 15761, ASME B16.34

Testing Standard: API 598

Hubluxe Engineering is a global supplier of Forged Steel Gate Valves, delivering high-performance flow control solutions to major industrial hubs including:

- Middle East & Eurasia (Oil & Gas): Saudi Arabia, UAE, Kuwait, Iran, Azerbaijan, Uzbekistan, and Russia.

- Africa (Mining & Processing): Nigeria, Ghana, Egypt, Tanzania, Morocco, Zambia, Kenya, South Africa, and Botswana.

- Asia Pacific (Infrastructure & Marine): Singapore, Indonesia, Thailand, Philippines, Cambodia, Vietnam, Malaysia, and Australia.

- South Asia: Nepal and Bhutan.

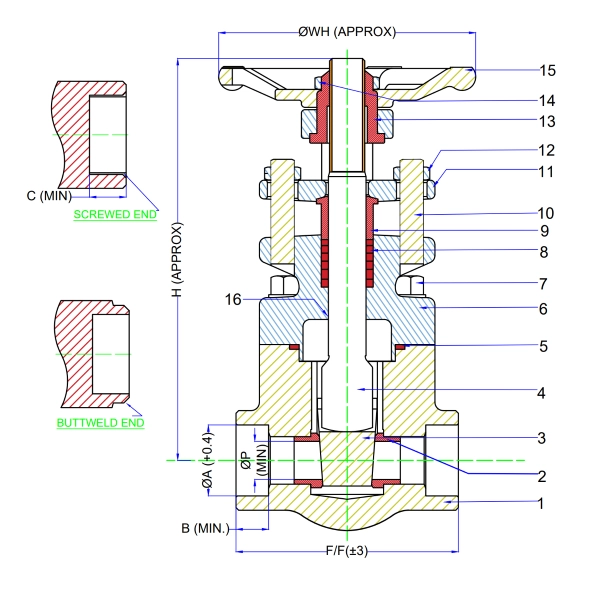

API 602 Gate Valve: Cross Section & Internal Construction:

Forged steel gate valve parts list:

| Sr. No. | Parts | Materials |

|---|---|---|

| 1 | Body | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 2 | Seat Ring | ASTM A 276 TYPE SS-410 / 304 / 304L / 316 / 316L |

| 3 | Wedge | ASTM A 217 GR. CA-15 / CF8 / CF3 / CF8M / CF3M |

| 4 | Stem | ASTM A 182 GR. F6a / F304 / F304L / F316 / F316L |

| 5 | Gasket | SS-304 Spiral Wounded Graphite |

| 6 | Bonnet | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 7 | Hex Bolt | ASTM A 193 GR.B7 / B8 / B8M |

| 8 | Gland packing | Flexible Graphite Rings |

| 9 | Gland Bush | ASTM A 276 TYPE SS-410 / 304 / 304L / 316 / 316L |

| 10 | Stud | ASTM A 193 GR.B7 / B8 / B8M |

| 11 | Gland Flange | ASTM A 105 / F304 / F316 / F11 / F22 |

| 12 | Stud Nut | ASTM A 194 GR. 2H / B8 / B8M |

| 13 | Yoke Sleeve | BS970: 1955 EN1A |

| 14 | Stem Nut | ASTM A 194 GR. 2H / B8 / B8M |

| 15 | Hand Wheel | SG IRON / MI |

| 16 | Back seat | Integral |

ANSI Class 800 valves are highly suitable in applications that require robust performance under high pressure in:

- Nuclear & thermal power generation

- Cement Industries

- Iron & Steel Mills

- Water treatment

- Steam and condensate lines

- High-pressure utility systems

- Oil & Gas Industries

- Pharmaceutical industries

- Paper & pulp industries

- Petrochemcial Industries

- Thermal Power Plants

FAQs (Frequently asked questions)

Find detailed answers to common questions about Forged Steel Gate Valve in our Knowledge centre.

A forged steel gate valve is an industrial high-pressure isolation valve made from forged steel, offering high strength, durability, and resistance to extreme pressure and temperature.

The valves are designed in accordance with API 602 / ISO 15761 / ASME B16.34 standards and are tested as per API 598, making an ideal for high temperature & pressure applications.

They are commonly used in:

- Oil and gas pipelines

- Power plants (thermal, nuclear)

- Petrochemical and chemical industries

- Steam and condensate lines

- High-pressure utility systems

They are ideal for isolation applications in high-pressure and high-temperature environments.