Forged Lift Check Valve Manufacturer

Key features:

Horizontal Piston Design– The piston mechanism utilises the line pressure to open & gravity to close. It prevents reverse flow in the pipeline

Integral hard face seat– The internals are designed with stelliting to prevent damages to the seat and combat erosion over a period of time

Stellite 6 hard facing– We offer stellite 6 hard facing on Disc & Plut to ensure long life span and less maintenance

Leakproof design– The body to bonnet joint is fully encased with spiral wound gasket (usually SS 304 / 316 with graphite filler) to prevent from any leakages

Body & Disc design types: Body can be bolted cover, welded cover or pressure seal cover (for high-pressure service) while disc type can be in Piston type lift disc or guided vertical motion for precise seating as per requirements.

Contact Hubluxe Engineering today for a competitive quote on Forged Lift Check Valve.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Hubluxe is a reliable forged lift check valve manufacturer offering precision-engineered valves for high-pressure industrial applications. Our forged lift check valves are designed to prevent backflow while ensuring smooth, vertical disc movement for efficient and reliable flow control solutions.

Manufactured using high-quality forged steel materials, these valves offer excellent strength, pressure resistance, and long operational life. Lift check valves are ideally suited for high-pressure and high-temperature systems where controlled flow direction is essential. Our forged steel lift check valves are commonly used in oil and gas, petrochemical, power generation, and refinery industries.

Available in 800 class pressure ratings, Hubluxe lift check valve 800 class comply with international standards such as API, ASME, and ASTM. Each valve undergoes rigorous testing to ensure leak-proof performance, dimensional accuracy, and operational safety. Precision-machined components reduce wear and ensure consistent performance under fluctuating pressure conditions. Each lift check valve 800 class unit is engineered for high-pressure service.

As an experienced forged lift check valve supplier, Hubluxe offers customizable options including body materials, end connections, and trim configurations to meet specific project requirements. Our valves are engineered to deliver dependable performance in demanding industrial environments while maintaining efficiency and safety.

Hubluxe is a trusted forged lift check valve manufacturer serving global industries. Contact us today for specifications or a competitive quotation.

Forged Lift Check Valve technical specifications:

- Product: ‘Hubluxe’ Forged Lift Check Valve

Size: 15 mm – 50 mm (1/2” – 2”)

- Material of construction (MOC): Carbon Steel – A105, LF / Stainless steel – F304, F304L, F316, F316L / Duplex steel – F51, F53, F55

- Trim: 13% Cr. Steel, Stellite 6

- End connection: Screwed End, Socket Weld End, Butt Weld End

Design options: Lift type design welded & renewable seat rings

- Operation: Self

- Design Standard: BS 5352, API 602, ISO 15761, ASME B16.34

Inspection & Testing standards: API 598

Pressure Class rating: ANSI 150#, 300#, 600#, 800#, 1500#, 2500#

Hubluxe Engineering is a global supplier of Forged Lift Check Valves, delivering high-performance flow control solutions to major industrial hubs including:

- Middle East & Eurasia (Oil & Gas): Saudi Arabia, UAE, Kuwait, Iran, Azerbaijan, Uzbekistan, and Russia.

- Africa (Mining & Processing): Nigeria, Ghana, Egypt, Tanzania, Morocco, Zambia, Kenya, South Africa, and Botswana.

- Asia Pacific (Infrastructure & Marine): Singapore, Indonesia, Thailand, Philippines, Cambodia, Vietnam, Malaysia, and Australia.

- South Asia: Nepal and Bhutan.

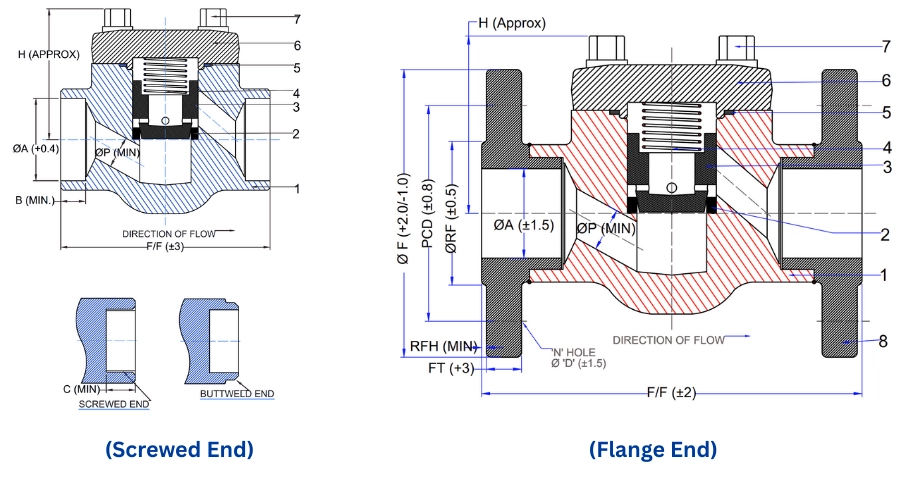

Forged Lift Check Valve: Cross Section & Internal Parts List:

Forged Lift Check valve SCREWED END parts list:

| Sr. No. | Parts | Materials |

|---|---|---|

| 1 | Body | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 2 | Seat Ring | ASTM A 182 GR. F6a / F304 / F304L / F316 / F316L |

| 3 | Plug | ASTM A 276 TYPE SS-410 / 304 / 304L / 316 / 316L |

| 4 | Spring | ASTM A 313 GR. SS-304 / 304L / 316 / 316L |

| 5 | Gasket | SS-304 Spiral Wounded Graphite |

| 6 | Check Plate | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 7 | Hex bolt | ASTM A193 Gr. B7 / B8 / B8M |

Forged Lift Check valve FLANGE END parts list:

| Sr. No. | Parts | Materials |

|---|---|---|

| 1 | Body | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 2 | Seat Ring | ASTM A 182 GR. F6a / F304 / F304L / F316 / F316L |

| 3 | Plug | ASTM A 276 TYPE SS-410 / 304 / 304L / 316 / 316L |

| 4 | Spring | ASTM A 313 GR. SS-304 / 304L / 316 / 316L |

| 5 | Gasket | SS-304 Spiral Wounded Graphite |

| 6 | Check Plate | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

| 7 | Hex bolt | ASTM A193 Gr. B7 / B8 / B8M |

| 8 | Flange | ASTM A105 / F304 / F304L / F316 / F316L / F5 / F9 / F11 / F22 / F51 / F55 / F91 / LF2 |

Forged lift check valve applications:

- Nuclear & thermal power generation

- Cement Industries

- Iron & Steel Mills

- Water treatment

- Steam and condensate lines

- High-pressure utility systems

- Oil & Gas Industries

- Pharmaceutical industries

- Paper & pulp industries

- Petrochemcial Industries

- Thermal Power Plants

FAQs (Frequently asked questions)

Find detailed answers to common questions about Forged Lift Check Valve in our Knowledge centre.

A forged lift check valve is a type of simple valve. The functionality is to allow fluids to flow in one direction and prevent the backflow. It operates using a disc that lifts the seat when forward flow occurs and when flow reverses the disc drops back to prevent backflow.

It is an ideal for applications in steam, gas, liquid system.