Floating Ball Valve Manufacturer (1-Piece, 2-Piece & 3-Piece Design)

Key features:

Hubluxe Engineering manufactures a wide range of Industrial Ball Valves designed for various process control. From standard utility lines to highly corrosive chemical applications, our floating ball valve range ensures leak-free isolation and long service life.

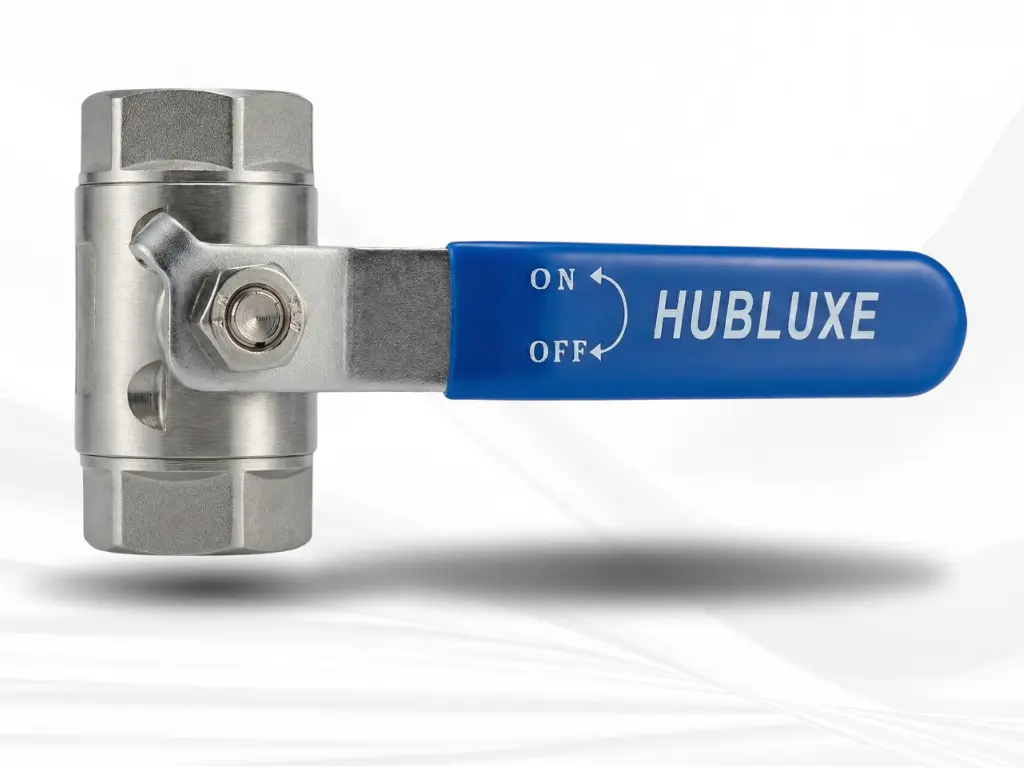

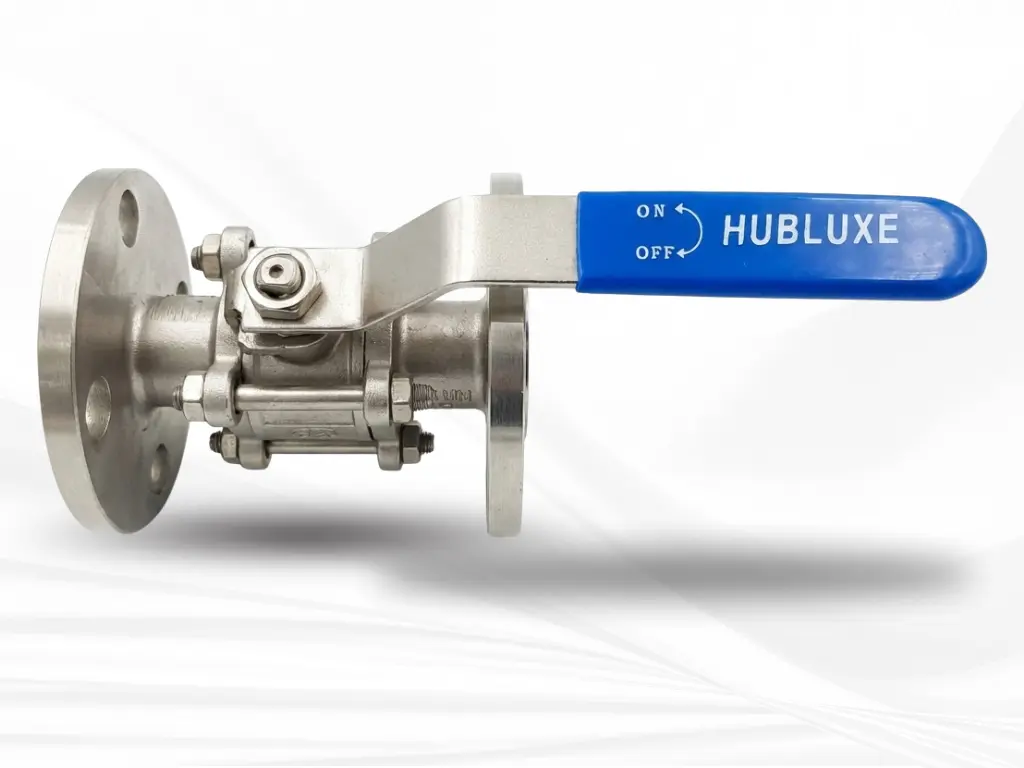

We offer floating ball valves in Screwed (Threaded) and Flanged ball valves available in following configurations:

- One Piece Design (1pc): Cost-effective, reduced bore solution.

- Two Piece Design (2pc): Standard full-bore isolation.

- Three Piece Design (3pc): Designed for easy inline maintenance.

- Lined Ball Valves: PTFE/PFA/FEP lined Ball valves for corrosives chemicals

Looking for Industrial Ball Valves? From cost-effective 1-Piece design, 2-piece design, 3-Piece to corrosion-resistant Lined Ball Valves, Hubluxe Engineering has the right ball valve solution for your applications.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

“Maximize your system’s efficiency by matching the valve design to your application”

- One-Piece Ball valve: Cost-effective choice for robust, leak proof design

- Two-Piece Ball Vale: High-performance isolation valve for demanding oil, gas, and steam lines.

- Three-Piece Ball Valve: The ultimate solution for ease of maintenance, allowing for quick inline repair to minimize plant downtime.

HUBLUXE Floating Ball Valves deliver reliable, leak-free shutoff for critical isolation services across oil & gas, chemical processing, and power generation. Engineered for durability, ease of maintenance, and consistent operation, HUBLUXE floating ball valves are widely used across oil & gas, chemical, water, and general industrial services.

Industrial Floating Ball Valve technical specifications:

Product: ‘HUBLUXE’ Floating Ball Valve

Size: 6 mm to 200 mm (1/4” to 8”)

Material of construction (MOC): CI / WCB / CF8 / CF8M / CF3 / CF3M

Pressure class: 150#, 300#

Bore size: Full Bore / Reduce Bore

End connections: Screwed End (BSP / NPT), Flange end (ASME B16.5), Butt weld end (ASME B16.25)

Mode of operation: Manual handwheel / Pneumatic / Hydraulic / Electrical actuator operated Ball valve

We export our Ball valves range worldwide: South Africa-Tanzania, Saudi Arabia, UAE, Azerbaijan, Russia, Kuwait, Zambia, Singapore, Indonesia, Thailand, Philippines, Australia, Botswana, Nepal, Bhutan, Egypt, Iran, Vietnam, Malayasia.

Industrial Floating Ball Valve applications:

- Water & wastewater treatment

- Oil & gas

- Petrochemicals

- Power generation

- HVAC

- LNG

- Cement plants

- Fertilisers

- Steel & Mining

- Sugar Mills

- Food & Beverages

- Pharmaceuticals

- Paper & Pulp

Screwed and Flanged Ball Valves (1PC / 2PC / 3PC):

Technical Data:

Size: 6 mm to 100 mm

Design & Mfg. Std.: BS5351 / ASME B16.34

Testing & Inspection: API 598 / BS 6755

Face to face: HUBLUXE Manufacturing standard

End connection: Screwed End (BSP/NPT)

150# Hydro Test Pressure details:

Hydro Body: 32 kg/cm2 [430 psig]

Hydro Seat: 22 kg/cm2 [315 psig]

Air / Pneumatic: 7 kg/cm2 [80 psig]

Technical Data:

Size: 25 mm to 100 mm

Design & Mfg. Std.: BS5351

Testing & Inspection: API 598

Face to face: HUBLUXE Manufacturing standard

End connection: Flange End (ASME B16.5)

150# Hydro Test Pressure details:

Hydro Body: 32 kg/cm2 [430 psig]

Hydro Seat: 22 kg/cm2 [315 psig]

Air / Pneumatic: 7 kg/cm2 [80 psig]

Technical Data:

Size: 15 mm to 150 mm

Design & Mfg. Std.: BS5351 / ASME B16.34 / ISO 17292

Testing & Inspection: API 598 / BS 6755

Face to face: ASME B16.10

End connection: Flange End (ASME B16.5)

Operation: Bare stem, Lever operated, Gear operated, Electrical actuator operated

150# Hydro Test Pressure details:

Hydro Body: 32 kg/cm2 [430 psig]

Hydro Seat: 22 kg/cm2 [315 psig]

Air / Pneumatic: 7 kg/cm2 [80 psig]

300# Hydro Test Pressure details:

Hydro Body: 80 kg/cm2 [1140 psig]

Hydro Seat: 56 kg/cm2 [815 psig]

Air / Pneumatic: 7 kg/cm2 [80 psig]

Technical Data:

Size: 15 mm to 100 mm

Design & Mfg. Std.: BS5351 / ISO 17292

Testing & Inspection: API 598 / BS 6755

End connection: Screwed End, Socket Weld End (ASME B16.11)

Operation: Lever operated, Pneumatic actuator operated

150# Hydro Test Pressure details:

Hydro Body: 32 kg/cm2 [430 psig]

Hydro Seat: 22 kg/cm2 [315 psig]

Air / Pneumatic: 7 kg/cm2 [80 psig]

Technical Data:

Size: 15 mm to 100 mm

Design & Mfg. Std.: BS5351 / ISO 17292

Testing & Inspection: API 598 / BS 6755

End connection: Screwed End, Socket Weld End (ASME B16.11)

Operation: Lever operated, Pneumatic actuator operated

150# Hydro Test Pressure details:

Hydro Body: 32 kg/cm2 [430 psig]

Hydro Seat: 22 kg/cm2 [315 psig]

Air / Pneumatic: 7 kg/cm2 [80 psig]

FAQs (Frequently asked questions)

Find detailed answers to common questions about Floating Ball valves in our Knowledge centre.

A Ball valve is a shutoff valve that consist of a rotating hollow ball (and solid balls) to control the flow media. The ball rotates 90 degrees (quarter turn) with the help of handle or driving device like actuator to either OPEN or CLOSE the valve.

The ball valves are also known as quarter turn ball valves.

Ball valve is most widely used valves in various application due to their durability, reliability, tight sealing ability & of course economical.