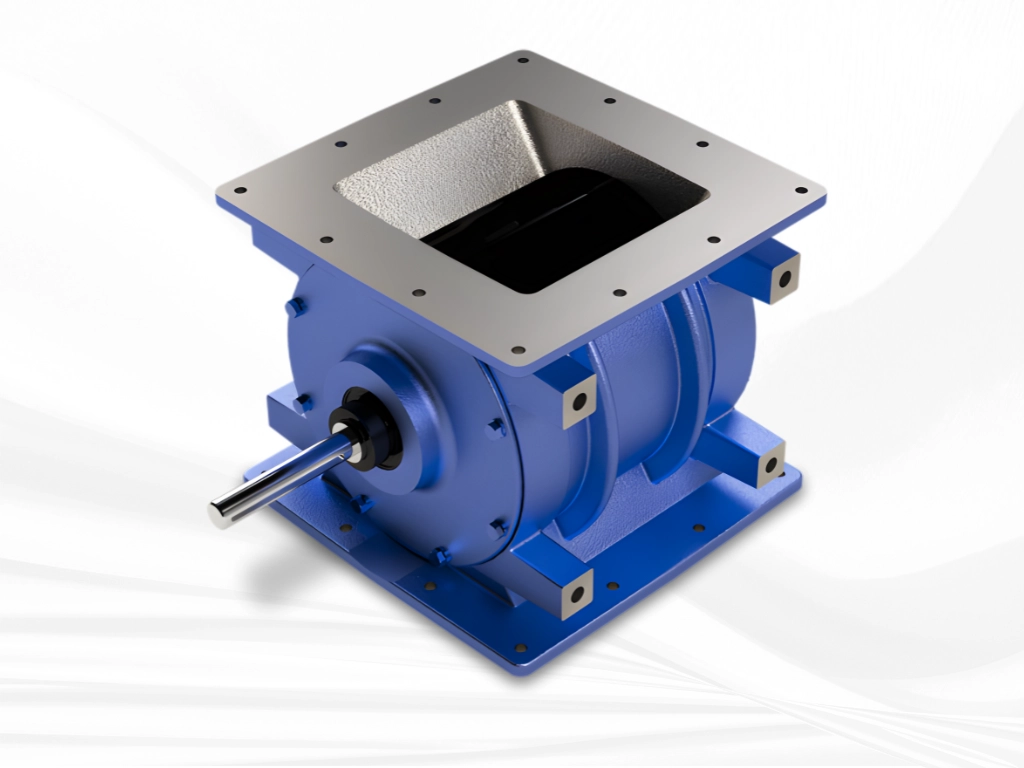

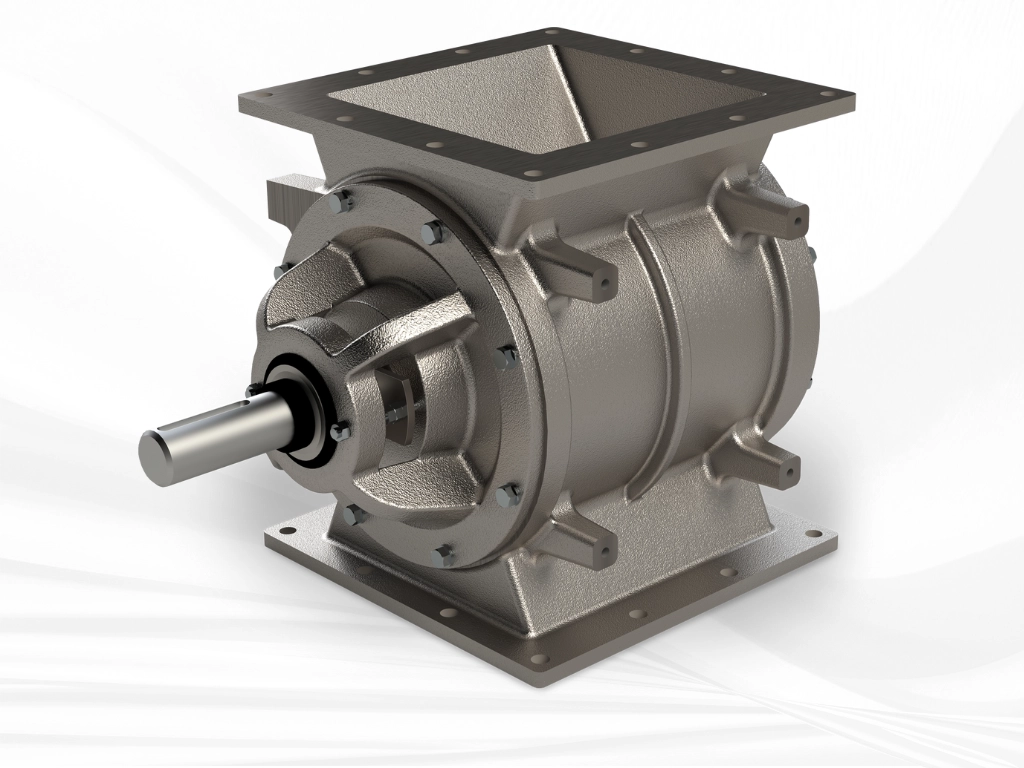

Drop Through Rotary Airlock Valve (Gravity Feed)

Key features:

- Material of construction (MOC): Standard Cast iron housing with option to upgrade in SS304 / SS316 or SS316L

- Consistent performance: The valve is designed to help gravity assisted material with minimum air loss

- Efficient Rotor design: Rotor Vane is designed to efficiently discharge the materials

- Drive configurations: Available in multiple configurations such as Direct coupled drive, Chain drive, Bare drive or V belt systems

- Applications: The drop through rotary valves is used in various industries including- Dairy, Food, Chemicals, Plastics, Pet Foods, Pharmaceuticals and other bulk material handling applications

Contact Hubluxe Engineering today for a competitive quote on Drop Through Rotary Valve (RAV)

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Whether your system is handling bulk fine powders, plastic granules, abrasive or bulk solids, HUBLUXE valves are engineered to prevent air leakage and maximise the efficiency of dust collections, silos and cyclones.

Our gravity feed rotary valve design is specifically engineered for systems where material falls vertically into the rotor, making it the most efficient rotary airlock valve for dust collector and silo discharge applications.

Each standard drop through RAV features precision rotor clearances to minimize air leakage, which is critical for the performance of an industrial RAV for silo discharge in cement and chemical industries. Our rotary feeder valve gravity discharge design supports continuous operation.

Choosing a reliable drop through airlock manufacturer ensures your process maintains a high-pressure seal while facilitating a consistent discharge of powders and granules.

Drop Through Rotary Valve (RAV) technical specifications:

Product: ‘HUBLUXE’ Drop Through Rotary Valve

Size: 100 MM to 600 MM (4” to 24”)- (Higher sizes on request)

Body option: Round, Square, Rectangular (depending on the customer’s requirement)

Rotor option: Open fixed bladed rotor, scalloped rotor, closed rotor, Open adjustable bladed rotor (depending on the application type)

Material of construction: Cast Iron, Cast Steel, Cast SS 304, 316, 316L (special material on request)

Drive: Coupled Gearbox Motor, Chain & Sprocket design, V-Belt

Industries: Dairy, Food, Chemicals, Plastics, Pet Foods, Pharmaceuticals and other bulk material handling applications

Our Drop through rotary airlock valves is designed for Application-Focused Engineering: We don’t just sell valves; we provide solutions. Our engineers will review your requirements, suggest suitable model, and recommend suitable solutions.

Drop Through Rotary Airlock valve applications:

- Dairy

- Food

- Chemicals

- Plastics

- Pet Foods

- Pharmaceuticals and

- other bulk material handling applications

FAQs (Frequently asked questions)

Find detailed answers to common questions about Double Disc Gate valves in our Knowledge centre.

In drop through rotary valve, materials fall directly into the inlet of RAV and gets rotated by rotor (located in housing of RAV) to exit from outlet flange by gravity. It is an ideal solutions for handling dust collection, hoppers, silo, Cements, and bulk materials.