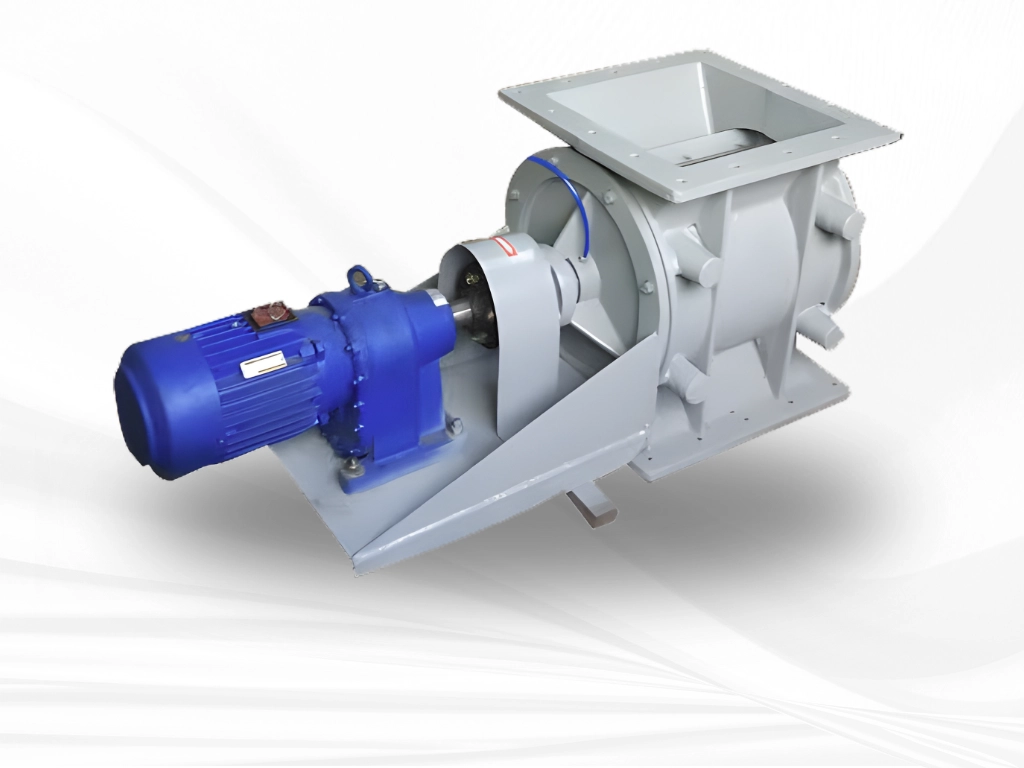

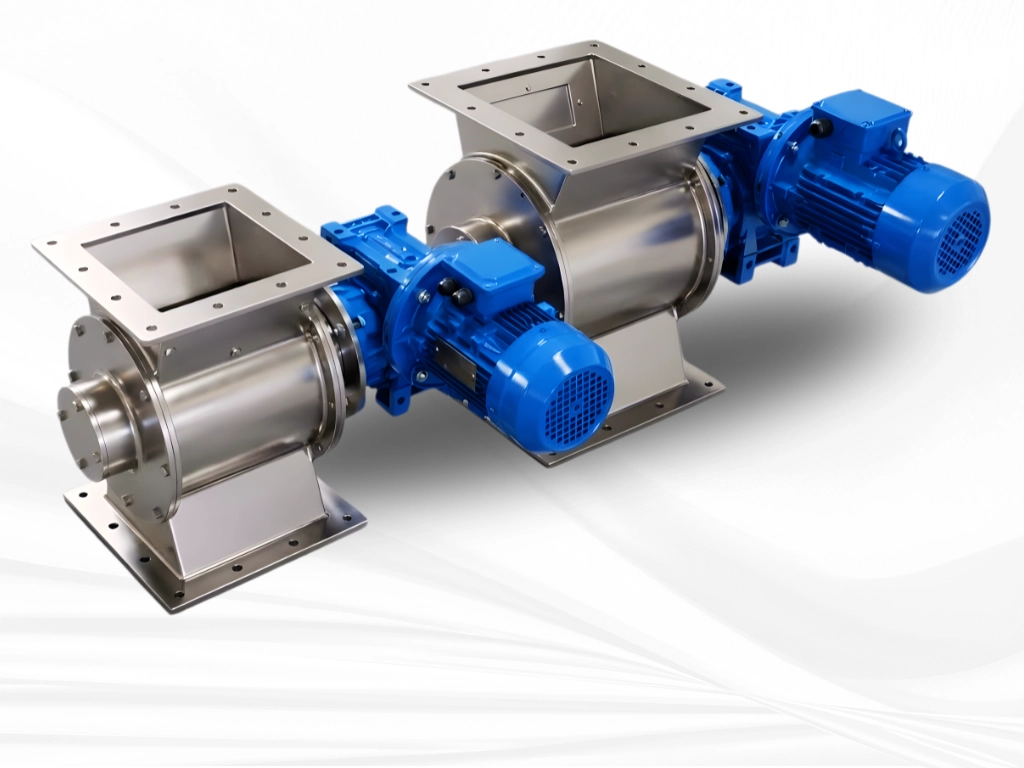

Direct Drive Rotary Airlock Valve (Gearbox Mounted)

Key features:

- Custom RAV design: RAV can be customised as per your requirements.

- Material of construction (MOC): Cast iron, MS, SS304 / SS316 depending on application.

- Size range: 100 mm to 600 mm (Higher size on request).

- Drive: Coupled (Rotor Shaft → Electric Motor + gearbox).

- This direct drive rotary valve reduces maintenance by eliminating chains or belts.

- Rotor type: Adjustable rotor with wide rotor options as per application needs (Closed end rotor, Open end rotor, Dust collector rotor, Shallow pocket rotor, Adjustable rotor tip, Rigid pocket rotor etc.).

- Less maintenance: Highly efficient & less maintenance required as compared to conventional chain drive rotary airlock valve.

- Common types of seals used in rotary airlock valves: Flexible rubber seals, Neoprene seals, Nitrile (Buna-N) seals, Metal to metal seals, Polyurethane seals.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

HUBLUXE manufactures & exports Direct Drive Rotary Airlock Valve in which the rotor shaft of the RAV is directly coupled to an electric motor & gearbox for operation. A gearbox mounted rotary airlock valve ensures precise material feeding.

Hubluxe is a trusted rotary airlock valve manufacturer serving global industries.

Direct Coupled Rotary Valve technical specifications:

Product: ‘HUBLUXE’ Direct Drive Rotary Airlock valve

Size range: 100 MM to 600 MM (4” to 24”)- (Higher sizes on request)

Body option: Round, Square, Rectangular (depending on the customer’s site requirement)

Rotor option: Open fixed bladed rotor, scalloped rotor, closed rotor, Open adjustable bladed rotor (depending on the application type)

Material of construction: Cast Iron, Cast Steel, Cast SS 304, 316, 316L (special material on request)

Capacity: 1 TPH to 300 TPH (as per customer request)

Drive: Coupled Gearbox Motor

Application: Pneumatic conveying systems, Dust collection and filtration discharge, Hopper and silo unloading, Controlled material feeding and metering

Industries: Food Industries, Process Industries, Dairy, Pharma, Chemicals, Plastic, Pet Foods, Dry & Bulk material handling industries

Our Airlock Valve with Gearbox is designed & engineered to combat corrosion, staining issues, rusting thus making them perfect choice for Food Industries, Process Industries, Dairy, Pharma, Chemicals, Plastic, Pet Foods, Dry & Bulk material handling industries.

Direct Couple Rotary Airlock Valve applications:

- Spices Industries

- Food Industries

- Process Industries

- Dairy

- Pharma & Chemicals

- Plastic

- Dry & Bulk material handling

FAQs (Frequently asked questions)

Find detailed answers to common questions about Direct Drive Rotary Airlock Valve (Direct Coupled) in our Knowledge centre.

Direct drive or direct coupled rotary airlock valve as the name says – it connects the rotor shaft of the RAV to the motor & gearbox mounted to rotate the vanes. The need of chain & sprocket designs is eliminated making them preferred choice for applications where hygiene, safety, reliability & precision are prioritized over initial cost.

The following factors should be taken into consideration while selecting a Rotary Airlock valve:

- Materials to be handled such as abrasive, corrosive, moisture contents and particle size

- Flow rate of the materials

- Pressure drops calculations (High pressure drop will reduce the efficiency of RAV and increase energy costs – Instead select the RAV with a tight seal and correct sized rotor to minimise the energy expense)

- Right selection of RAV for Pneumatic conveying systems: Drop through Rotary Airlock Valves works well with handling materials like coffee beans, grains, poly granules etc. While materials like cocoa powder, Flour, Chemicals powders, Milk powders etc. works well with Blow through rotary airlock valves.

- Easy Repair & maintenance: Choose the Rotary airlock valve which provides convenient access to rotor and vanes thus minimizing the downtime and lower maintenance costs.