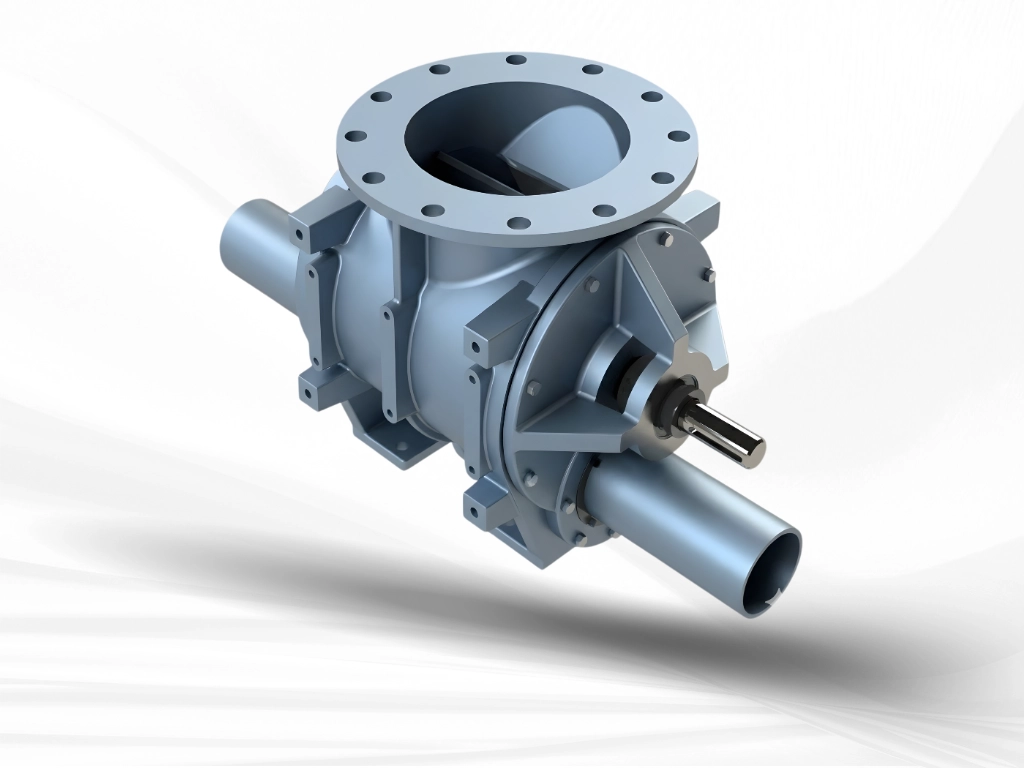

Blow Through Rotary Airlock Valve for Pneumatic Conveying

Key features:

- Hubluxe Blow Through Rotary Airlock valve is specifically designed for applications requiring discharge into pneumatic conveying line

- An ideal solution for handling cohesive or sticky powders such as cocoa, milk powders, Flour, Spices as they prevent building up ensuring smooth discharge

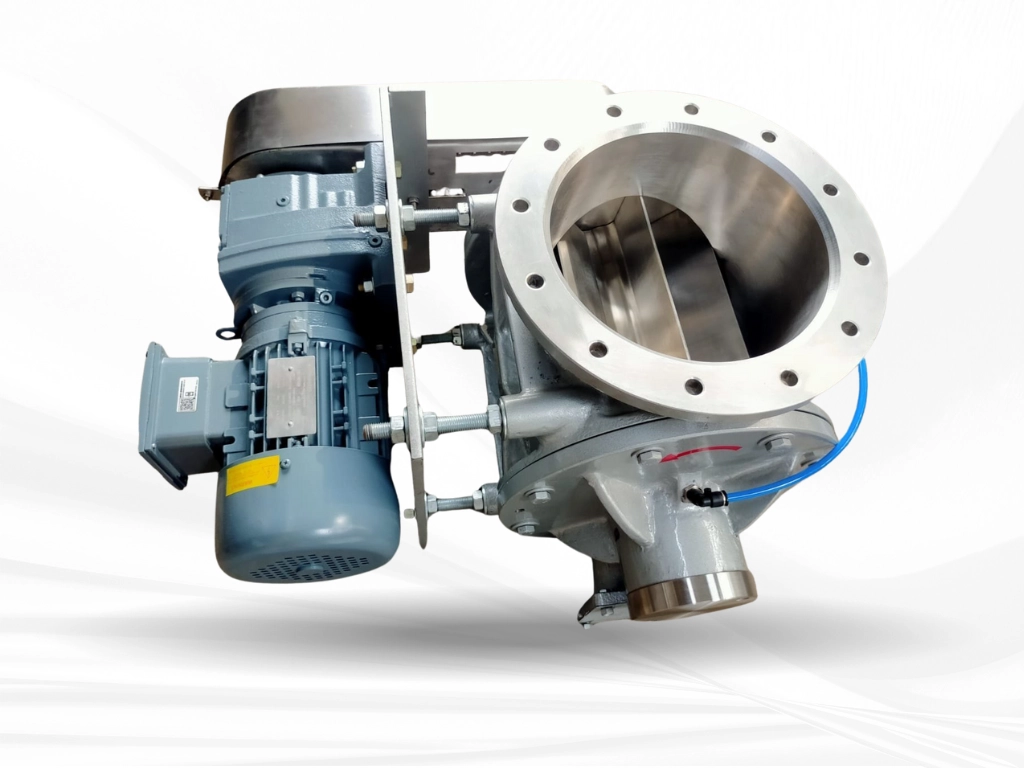

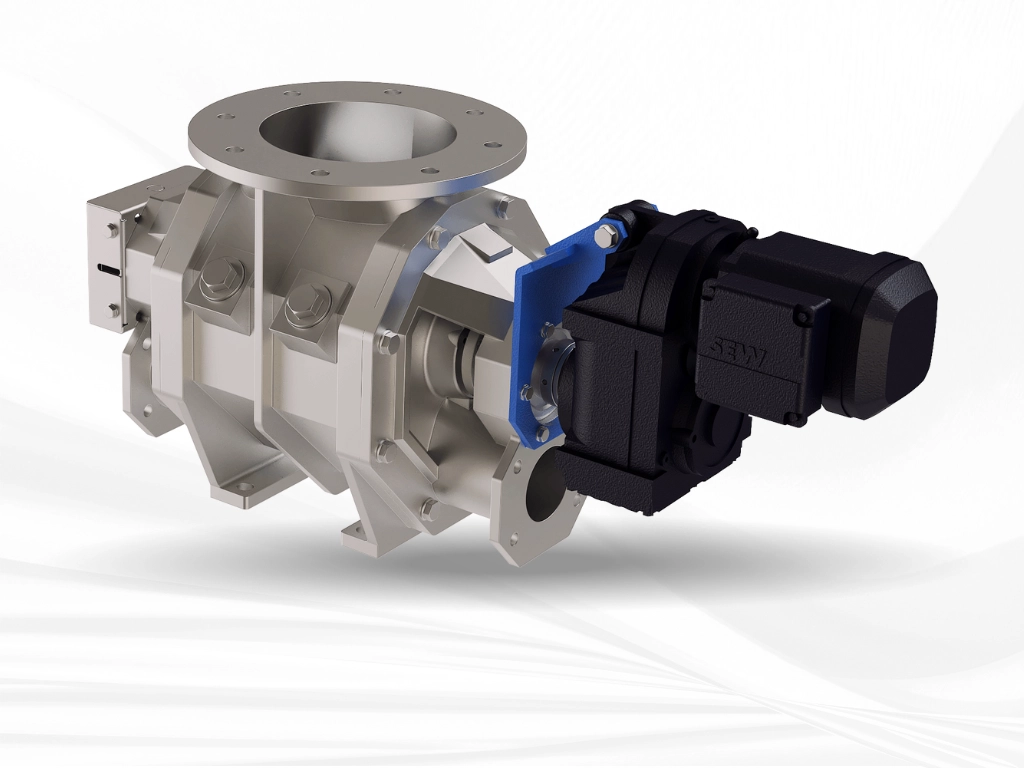

- Robust construction: The RAV design is heavy duty available in MOC such as cast Iron, Stainless Steel (SS304, SS316, SS316L)

- Adjustable rotor blade option to handle different material properties

- It features innovative & larger vane pocket design

- Longer service life, less maintenance, and very cost competitive Blow Through Rotary airlock valve

- Optimised for low-clearance installations where a drop-through may not fit

Contact Hubluxe Engineering today for a competitive quote.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

Hubluxe Engineering manufactures high pressure rotary airlock valve specifically designed for dilute-phase pneumatic conveying systems. Unlike standard drop-through models, our blow-through design integrates the conveying line directly through the rotor pockets. This aerodynamic scouring action prevents material buildup, making it the industry standard for handling sticky, cohesive, and light powders like flour, cocoa, and chemical dusts.

Rotary airlock valve for pneumatic conveying: The Hubluxe Blow Through Rotary Airlock Valve (RAV) functions as both a continuous process seal and a material feeder. Engineered for high-performance in pneumatic conveying systems, this valve connects directly to the conveying line, ensuring optimal airlock sealing between pressurized and non-pressurized zones.

Designed for Cohesive & Sticky Applications Standard rotary valves often fail when handling cohesive materials due to pocket clogging. The Hubluxe Blow Through design utilizes the pneumatic airstream to purge the rotor pockets with every rotation. This self-cleaning action ensures consistent bulk density and flow efficiency for challenging materials such as cement, fly ash, pharmaceutical powders, and food ingredients.

Integration & Performance Ideal for retrofitting into existing systems, our valves facilitate controlled discharge from silos, hoppers, and bag filters directly into the pneumatic stream. Available in Cast Iron, MS and Stainless Steel, Hubluxe valves maintain a precise rotor-to-housing clearance to minimize air leakage and maximize system pressure stability. As a trusted rotary airlock valve manufacturer, we deliver reliable rotary airlock valve solutions.

Technical specifications:

- Product: ‘HUBLUXE’ Blow through rotary airlock valve

- Size range: 100 MM to 600 MM (4” to 24”)- (Higher sizes on request)

- Body option: Round, Square, Rectangular (depending on the customer’s requirement)

- Rotor option: Open fixed bladed rotor, scalloped rotor, closed rotor, Open adjustable bladed rotor (depending on the application type)

- Material of construction: Cast Iron, Cast Steel, Cast SS 304, 316, 316L (special material on request)

- Capacity: 1 TPH to 300 TPH (as per customer request)

- Drive: Coupled Gearbox Motor, V-Belt

- Application: Pneumatic conveying systems, Dust collection and filtration discharge, Hopper and silo unloading, Controlled material feeding and metering

- Industries: Food Industries, Process Industries, Dairy, Pharma, Chemicals, Plastic, Pet Foods, Dry & Bulk material handling industries

Applications:

- Spices Industries

- Sticky Powder like Cocoa, Milk powder, Flour or cohesive powders

- Pneumatic conveying lines

- Food Industries

- Process Industries

- Dairy

- Pharma & Chemicals

- Plastic

- Pet Foods

- Dry & Bulk material handling industries

FAQs (Frequently asked questions)

Find detailed answers to common questions about Blow Through Rotary Airlock Valve in our Knowledge centre.

Unlike Drop through Rotary Airlock valve, a Blow through Rotary Airlock Valves don’t have an outlet flange on the bottom side. The bottom part of the RAV is either smooth or trough, which is where pneumatic line system connects and run through bottom of the valve.

Materials feeding is same as drop through, as the rotor runs passing the materials downside of the valve it is “Blown” directly out of the rotor pockets into the conveying systems down the line.

This type of valves is primarily used for free flowing, non-cohesive materials such as rice, coffee, beans, sugar, grains etc.

The main difference lies in the connection. A Drop Through RAV uses gravity to discharge material into a feeding shoe or hopper below. In contrast, a Blow Through RAV connects directly into the pneumatic conveying line. The conveying air passes through the valve’s rotor pockets, making it more efficient for low-headroom installations and sticky materials.

You should use a Blow Through valve when vertical space (headroom) is limited or when handling cohesive, sticky, or light powders. Because the pneumatic airstream passes directly through the rotor, it provides a “self-cleaning” action that purges materials like cocoa, flour, or starch that would otherwise clog a standard gravity valve.