Bidirectional Knife Gate Valves for Slurry & Viscous Fluids

“Zero leakage High-Performance Bi direction Knife Gate Valve for slurry, viscous, solid-filled fluids & Wastewater”

Hubluxe Engineering is recognized as one of the leading bi directional knife gate valve manufacturers in India.

The application of bi direction knife gate valves are in those areas where flow direction can change, such as mining, pulp & paper, Cement, power plants, chemical & pharma, food processing etc.

The bi direction knife gate valve has a unique body & seat design to prevent clogging and ensure tight shut off even with suspended solids present in it.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

In complex piping networks like Wastewater Treatment and Paper Pulp lines, backflow is a constant challenge. Standard knife gate valves often leak when pressure is applied from the counter-flow direction, leading to clogging and downtime.

Hubluxe Engineering’s Bidirectional Knife Gate Valves utilize a U-shaped resilient seat that provides a Zero Leakage seal against pressure from either direction. The gate cuts through suspended solids, ensuring positive isolation without the risk of wedge-locking or sediment buildup.

Note: For application that requires one directional flow and cost optimization – see our unidirectional knife gate valves range.

MSS-SP-81 Bidirectional Knife Gate valves technical specifications are as follows:

| Parameter | Specification |

|---|---|

| Product | HUBLUXE Bidirectional Knife gate valve |

| Size | 50 mm – 600 mm (2-inch to 24-inch) |

| Valve design Type | Bidirectional Knife Gate valve (KGV) |

| Pressure rating | PN6 / PN10 / PN16 / 150# |

| Material of construction (MOC) | Cast Iron / Ductile Iron / GGG40 / Cast Steel (WCB) / SS304 (CF8) / SS316 (CF8M) / SS316L (CF3M) – other materials on request |

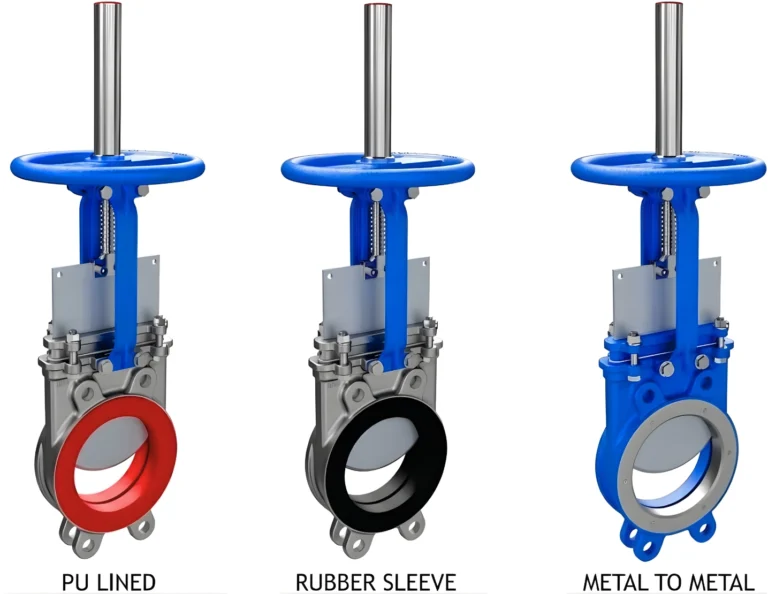

| Seat options | Metal to Metal / Soft seat (EPDM / Nitrile / Viton / Silicone / PTFE) / PU lined / Rubber sleeve |

| Lug options | Full Lug / Semi Lug / Double Flange / Square type |

| Gland Packing options | Pure PTFE / PTFE impregnated synthetic fiber / PTFE w/Buna-N quad seal / PTFE w/Viton quad seal / PTFE w/EPDM quad seal / PTFE w/Copper Wiper / Graphite |

| Operation | Manual / Pneumatic / Chain wheel operated / Electrical actuator / Bare shaft / Gearbox operated / Manual override |

| Applications | Paper & pulp / Waste water treatment plants / Power plants / Food & Beverage / Mining & Steel plant / Oil & Gas / Chemical plant / Pharma & Sugar Industries / Bulk materials & slurry applications |

| Standard flange connection | PN10 & ANSI B16.5 (150#) with Table ‘E’ & ‘D’ / PN6 / PN16 / PN25 / ANSI125 |

| Design standard | MSS-SP-81 |

| Testing standard | MSS-SP-81 |

| Face to face standard | MSS-SP-81 |

Bi directional knife gate valve seat options:

Note: The pressures indicated below can be used in both directions of the bi directional knife gate valve:

- DN 50 – DN 250 [10 bar]

- DN 300 – DN 400 [6 bar]

- DN 450 [5 bar]

- DN 500 – DN 600 [4 bar]

The Bidirectional knife gate valves from HUBLUXE ENGINEERING are suitable for:

- Wastewater Treatment Plants – sludge, effluent, and thickened biosolids

- Mining & Mineral Processing – For abrasive ore slurries and tailings

- Power Plants – bottom ash, fly ash, and FGD slurries

- Pulp & Paper – stock lines, recycled pulp, and rejects handling

- Chemical & Process Industries – viscous, corrosive or abrasive chemical mixtures

- Food & Beverage – where hygienic or CIP-compatible designs are required

FAQs (Frequently asked questions)

Find detailed answers to common questions about Bidirectional Knife Gate Valve in our Knowledge centre.

A bi directional knife gate valve is designed to seal against the pressure from both sides. The bi directional knife gate valve is well suited in the application where flow direction can be from either direction.