Basket Strainer Manufacturer (Simplex Type)

Key features:

Robust & simple design: Compact design ensures installation in confined space

Highly efficient strainer: Basket strainer is more efficient as compared to Y type strainer as they offer extensive filtration

Easy to maintain: Cleaning & maintaining this strainer is easy as all the debris gets collected within the basket for easy cleaning

Large filtration area: Basket strainers have larger holding capacity than the Y type strainers and it features top removal of filters

Hubluxe Basket strainers is equipped with various options like Bolted Covers, Hinged covers, Lifting device

Minimum pressure drops during operation which can be used for both temporary and continuous operation

Contact Hubluxe Engineering – Fabricated Basket Strainer Manufacturer today for a competitive quote.

📞 Call / WhatsApp:

+91-8652075992, +91-9967552335

✉️ Email:

sales@hubluxe.com, info@hubluxe.com

As a leading industrial strainer manufacturer india, we provide high-performance industrial basket strainer designed for maximum efficiency and durability in industrial fluid systems.

All the valves are 100% tested to deliver reliable performance in accordance with API 598 and comply with international quality systems such as ISO 9001:2015, which make us one of the leading basket strainer manufacturer in India.

“Choose Hubluxe Engineering, a trusted basket strainer manufacturer in India, for durable and custom-fabricated industrial strainers.”

Basket Strainer (Pipeline Basket Strainer) technical specifications:

Product: ‘HUBLUXE’ Basket strainers

Size: DN 50 to DN 600 (2” to 24”)

Pressure rating: ANSI 150#, ANSI 300#, ANSI 600#

Body Material of construction (MOC): SA 516 Gr. 70 / SA 106 Gr. B / SS 304 / SS316 (L)

Strainer basket MOC: available in SS304, SS304L, SS316, SS316L

Face to face: ANSI B16.10

Shell wall thickness: As per pipe standard

Manufacturing & Design Std.: ASME B16.34

End connections: ANSI B16.5, 150#

- Hydro Test Pressure details:

- For class 150# Hydro shell – 225 psig (16 kg/cm2)

- Hydro Seat – 150 psig (10 kg/cm2)

Industrial Strainer types:

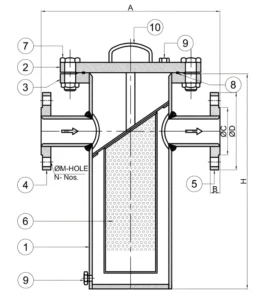

Industrial Basket strainer flange end parts list:

| # | Description | Material |

|---|---|---|

| 1 | Body | IS2062 / WCB / SS304 / SS316 |

| 2 | Top Cover | IS2062 / WCB / SS304 / SS316 |

| 3 | Body Cover | IS2062 / WCB / SS304 / SS316 |

| 4 | Inlet Flange | IS2062 / WCB / SS304 / SS316 |

| 5 | Outlet Flange | IS2062 / WCB / SS304 / SS316 |

| 6 | Screen | SS304 / SS316 |

| 7 | Cover Bolt & Nut | Carbon Steel / Stainless Steel |

| 8 | Gasket | Nitrile / EPDM / PTFE |

| 9 | Drain Plug | ASTM A105 |

| 10 | Lifting handle | Carbon Steel |

The Hubluxe Simplex Basket Strainer (Model shown in drawing) features a robust fabricated body designed for high-capacity liquid filtration. The internal Basket Element (Part 06) allows for gross particle removal to protect downstream pumps and meters.

Designed with a Top Removal cover, it ensures that maintenance teams can easily access and clean the screen without removing the strainer body from the pipeline.

As a leading simplex strainer manufacturer, Hubluxe Engineering provides custom-fabricated filtration solutions designed for low pressure drop and maximum debris removal in critical process pipelines.

Basket Strainer applications:

“Optimized for high-capacity liquid filtration, the primary Basket strainer application is to protect important equipment like pumps, meters, and valves from damaging by solid debris. Its large surface area ensures minimal pressure drop and easy maintenance, making it the ideal choice for various industrial applications.”

- Water treatment plant

- Natural gas & Air application

- Steam lines application

- HVAC systems

- Oil & gas industries

- Chemical industries

- Fertilizer plant

- Energy & Power plant

- Sugar industries

- Pharmaceutical industries

FAQs (Frequently asked questions)

Find detailed answers to common questions about Simplex Basket Strainer in our Knowledge centre.

A basket strainer is also known by bucket strainer name or bucket type strainer. A basket strainer is a mechanical filtration device which is used in pipelines to collect debris, unwanted solid particles etc. from flowing fluids, protecting important equipment from potential damages.

The principal of working is simple – it consists of perforated or mesh-lined removable basket that filters the fluid for any unwanted materials and collect it in strainer, which can be easily removed for cleaning out the debris.

It ensures smooth operation in various industrial applications.