sales@hubluxe.com |

The perfect Knife gate valve

“Hubluxe Engineering” is one of the leading knife gate valve manufacturer based in India, supplying high quality knife gate valves to different industries.

By using excellent state of the art manufacturing facility we are able to provide knife edge gate valves in premium quality with flexible pricing, in different sizes, models, material specifications as per customers application requirements.

Manual Knife Gate valve

Knife Gate valve

Pneumatic Knife Gate valve

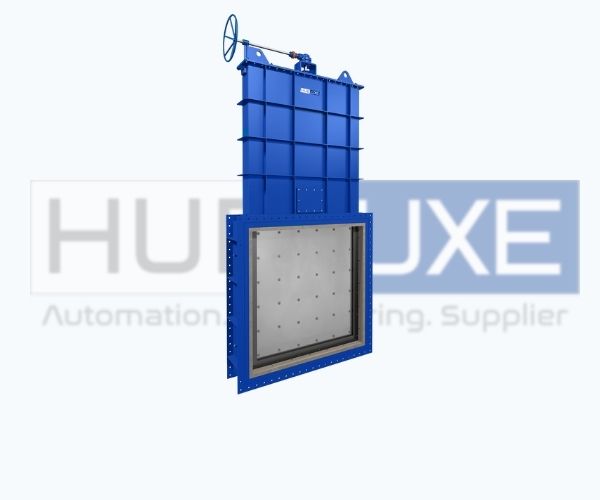

Square Knife Gate valve

There is no exact types of Knife gate valve. Most of the Knife gate valves are selected based on certain parameters such as Uni-directional or Bi-directional, Metal seated or soft seated and from operational point it is either Hand wheel operated, Pneumatic operated, gear operated or electrical actuated.

We manufacture following types of Knife Gate valves for wide area of application:

Types: Uni-directional, Bi-directional

Size: 50 mm to 2000 mm (larger size on request)

Body: Cast Iron, SGI, ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Gate: WCB, SS304, SS316, 317 Stainless Steel, Hastelloy® C, Monel®, Titanium

Seat ring: Metal to metal, V-Port, also available in EPDM/VITON/PTFE/NITRILE

Operation: Manual, Gear, Pneumatic, Electrical actuator & Chain operating

Actuator options: Direct Mounted Handwheel, Bevel Gear Operator, Double Acting Pneumatic Actuator, Hydraulic Actuator, Electrical Actuator

Working Pressure: 3 kg/cm2 to 10 kg/cm2 (45 psi to 150 psi)

Temperature: -40 deg. C to 1200 deg. C

Flange connection: ANSI B16.5 class 150#, EN1092 PN6/16/25, BS "D" & "E" ANSI 125

Port type: Two-lug, full lugged, Semi lugged, Flange design, Wafer flangeless

Design standard: MSS SP-81 which applies to metal seated knife gate valves while Resilient seated knife gate valves are not designed under MSS SP-81

Testing standard: As per MSS SP-81

Application: Pulp & paper, Mining, Primary Milling, Ash handling, Chemical plants, Food & beverages, Wastewater treatment, Process pumps

Types: Uni-directional, Bi-directional

Size: 50 mm to 2000 mm (larger size on request)

Body: Cast Iron, SGI, ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Gate: WCB, SS304, SS316, 317 Stainless Steel, Hastelloy® C, Monel®, Titanium

Seat ring: Metal to metal, V-Port, also available in EPDM/VITON/PTFE/NITRILE

Operation: Manual, Gear, Pneumatic, Electrical actuator & Chain operating

Actuator options: Direct Mounted Handwheel, Bevel Gear Operator, Double Acting Pneumatic Actuator, Hydraulic Actuator, Electrical Actuator

Working Pressure: 3 kg/cm2 to 10 kg/cm2 (45 psi to 150 psi)

Temperature: -40 deg. C to 1200 deg. C

Flange connection: ANSI B16.5 class 150#, EN1092 PN6/16/25, BS "D" & "E" ANSI 125

Port type: Two-lug, full lugged, Semi lugged, Flange design, Wafer flangeless

Design standard: MSS SP-81 which applies to metal seated knife gate valves while Resilient seated knife gate valves are not designed under MSS SP-81

Testing standard: As per MSS SP-81

Types: Uni-directional, Bi-directional

Size: 50 mm to 2000 mm (larger size on request)

Body: Cast Iron, SGI, ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Gate: WCB, SS304, SS316, 317 Stainless Steel, Hastelloy® C, Monel®, Titanium

Seat ring: Metal to metal, V-Port, also available in EPDM/VITON/PTFE/NITRILE

Operation: Manual, Gear, Pneumatic, Electrical actuator & Chain operating

Actuator options: Direct Mounted Handwheel, Bevel Gear Operator, Double Acting Pneumatic Actuator, Hydraulic Actuator, Electrical Actuator

Working Pressure: 3 kg/cm2 to 10 kg/cm2 (45 psi to 150 psi)

Temperature: -40 deg. C to 1200 deg. C

Flange connection: ANSI B16.5 class 150#, EN1092 PN6/16/25, BS "D" & "E" ANSI 125

Port type: Two-lug, full lugged, Semi lugged, Flange design, Wafer flangeless

Design standard: MSS SP-81 which applies to metal seated knife gate valves while Resilient seated knife gate valves are not designed under MSS SP-81

Testing standard: As per MSS SP-81

Types: Uni-directional, Bi-directional

Size: 50 mm to 2000 mm (larger size on request)

Body: Cast Iron, SGI, ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Gate: WCB, SS304, SS316, 317 Stainless Steel, Hastelloy® C, Monel®, Titanium

Seat ring: Metal to metal, V-Port, also available in EPDM/VITON/PTFE/NITRILE

Operation: Manual, Gear, Pneumatic, Electrical actuator & Chain operating

Actuator options: Direct Mounted Handwheel, Bevel Gear Operator, Double Acting Pneumatic Actuator, Hydraulic Actuator, Electrical Actuator

Working Pressure: 3 kg/cm2 to 10 kg/cm2 (45 psi to 150 psi)

Temperature: -40 deg. C to 1200 deg. C

Flange connection: ANSI B16.5 class 150#, EN1092 PN6/16/25, BS "D" & "E" ANSI 125

Port type: Two-lug, full lugged, Semi lugged, Flange design, Wafer flangeless

Design standard: MSS SP-81 which applies to metal seated knife gate valves while Resilient seated knife gate valves are not designed under MSS SP-81

Testing standard: As per MSS SP-81

Types: Uni-directional, Bi-directional

Size: 50 mm to 2000 mm (larger size on request)

Body: Cast Iron, SGI, ASTM A216 Gr. WCB, ASTM A351 Gr. CF8/CF8M, CF3, CF3M (and special grade materials on request)

Gate: WCB, SS304, SS316, 317 Stainless Steel, Hastelloy® C, Monel®, Titanium

Seat ring: Metal to metal, V-Port, also available in EPDM/VITON/PTFE/NITRILE

Operation: Manual, Gear, Pneumatic, Electrical actuator & Chain operating

Actuator options: Direct Mounted Handwheel, Bevel Gear Operator, Double Acting Pneumatic Actuator, Hydraulic Actuator, Electrical Actuator

Working Pressure: 3 kg/cm2 to 10 kg/cm2 (45 psi to 150 psi)

Temperature: -40 deg. C to 1200 deg. C

Flange connection: ANSI B16.5 class 150#, EN1092 PN6/16/25, BS "D" & "E" ANSI 125

Port type: Two-lug, full lugged, Semi lugged, Flange design, Wafer flangeless

Design standard: MSS SP-81 which applies to metal seated knife gate valves while Resilient seated knife gate valves are not designed under MSS SP-81

Testing standard: As per MSS SP-81

Application areas

- Pulp & paper

- Ash handling

- Primary Milling

- Mining

- Energy & Power

- Chemical plants

- Abrasive slurry materials

- Process industries

- Heavy oils

Interested to know more about Knife Gate valves?

We shall be glad to hear on your queries about the Knife Gate valves. Our team can aid in guiding and selecting the valves required for your most critical applications.

Business Phone

+91 22 27830855

+91 22 49714236